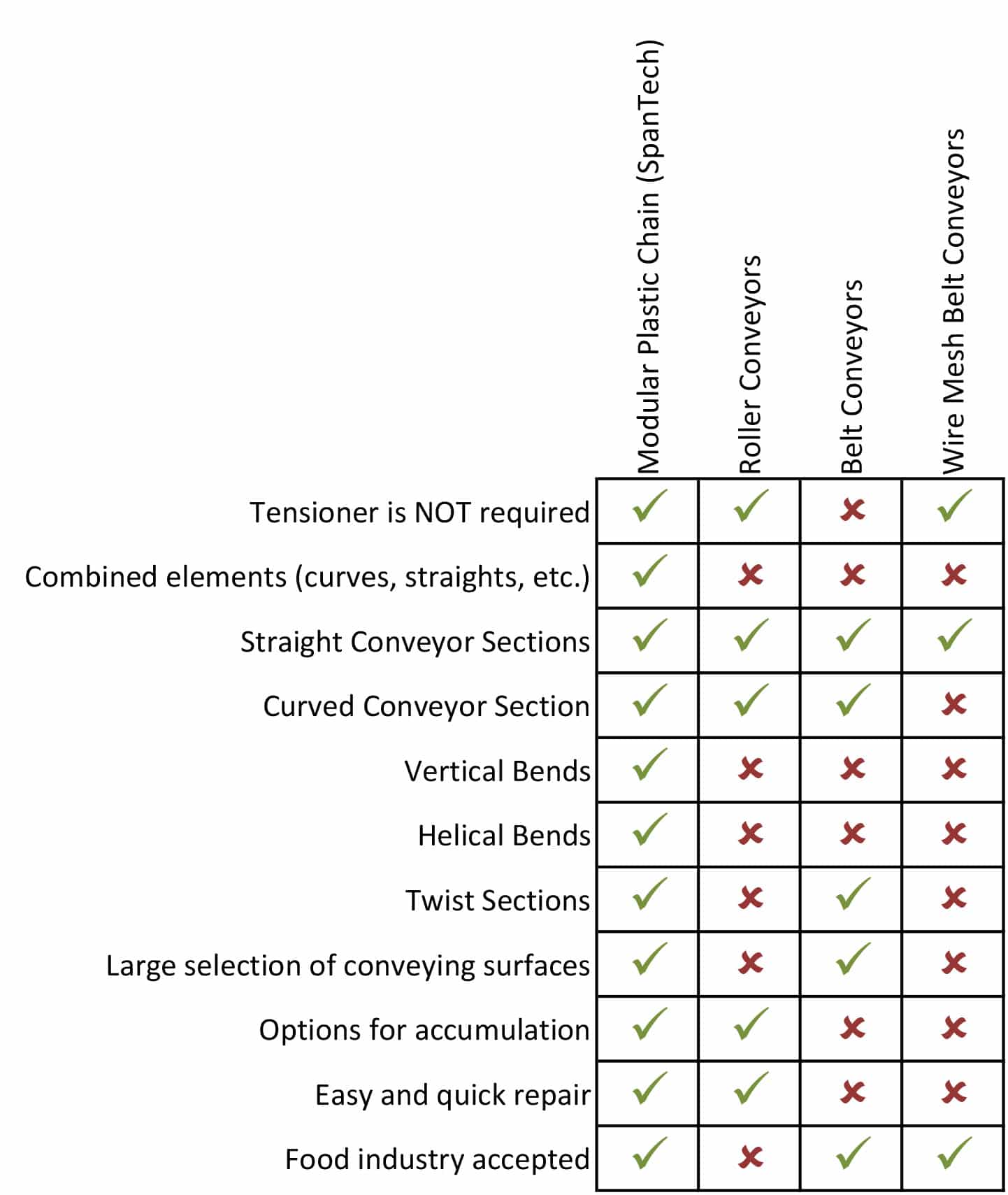

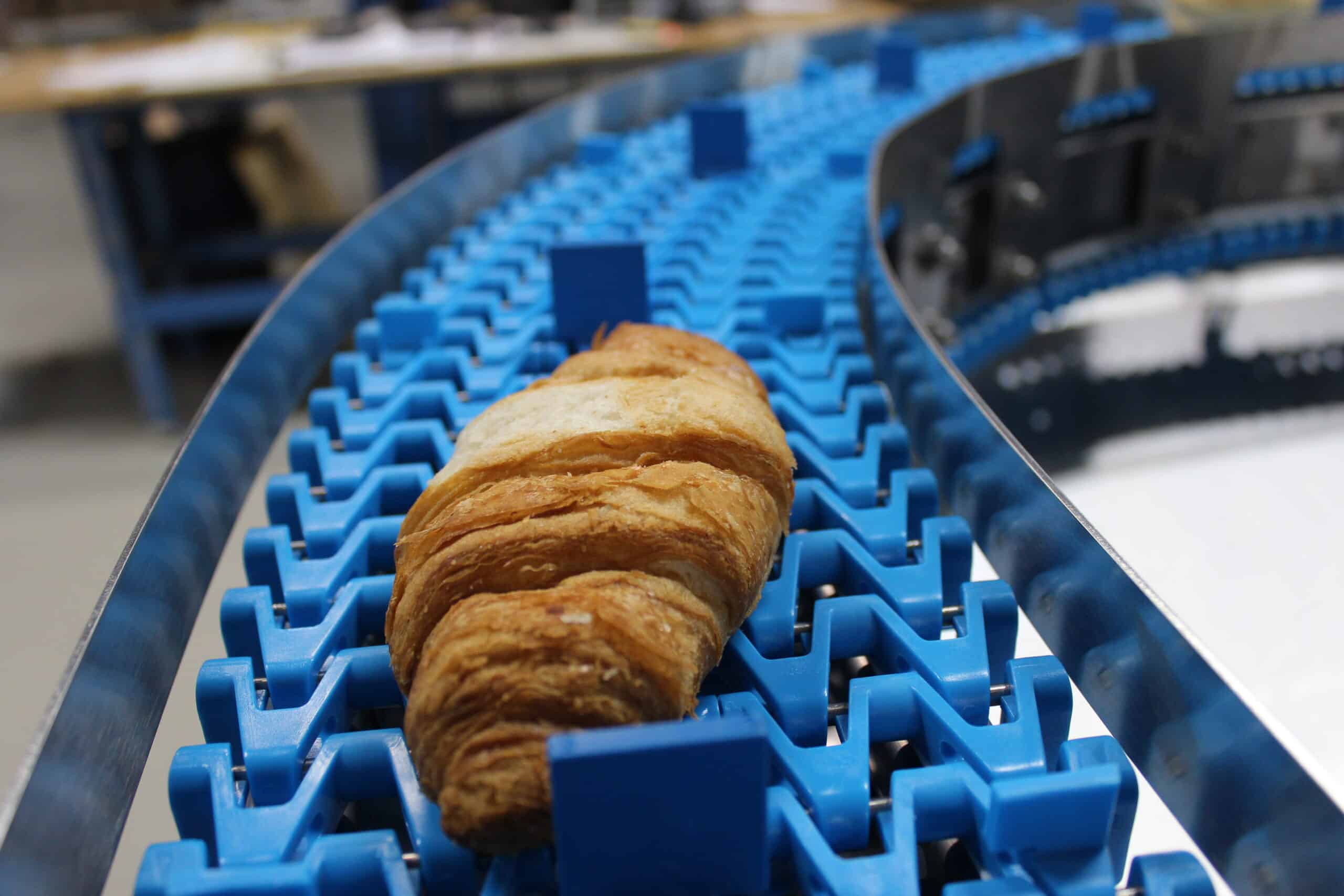

When choosing a conveying solution for your project, there are a wide variety of types of conveyors to choose from. Most people are familiar with roller conveyors or belt conveyors already. SpanTech makes Modular Plastic Chain Conveyors. They provide the most flexibility in design and the lowest total cost of ownership versus all other conveyor types.

Plastic Chain Has More Options

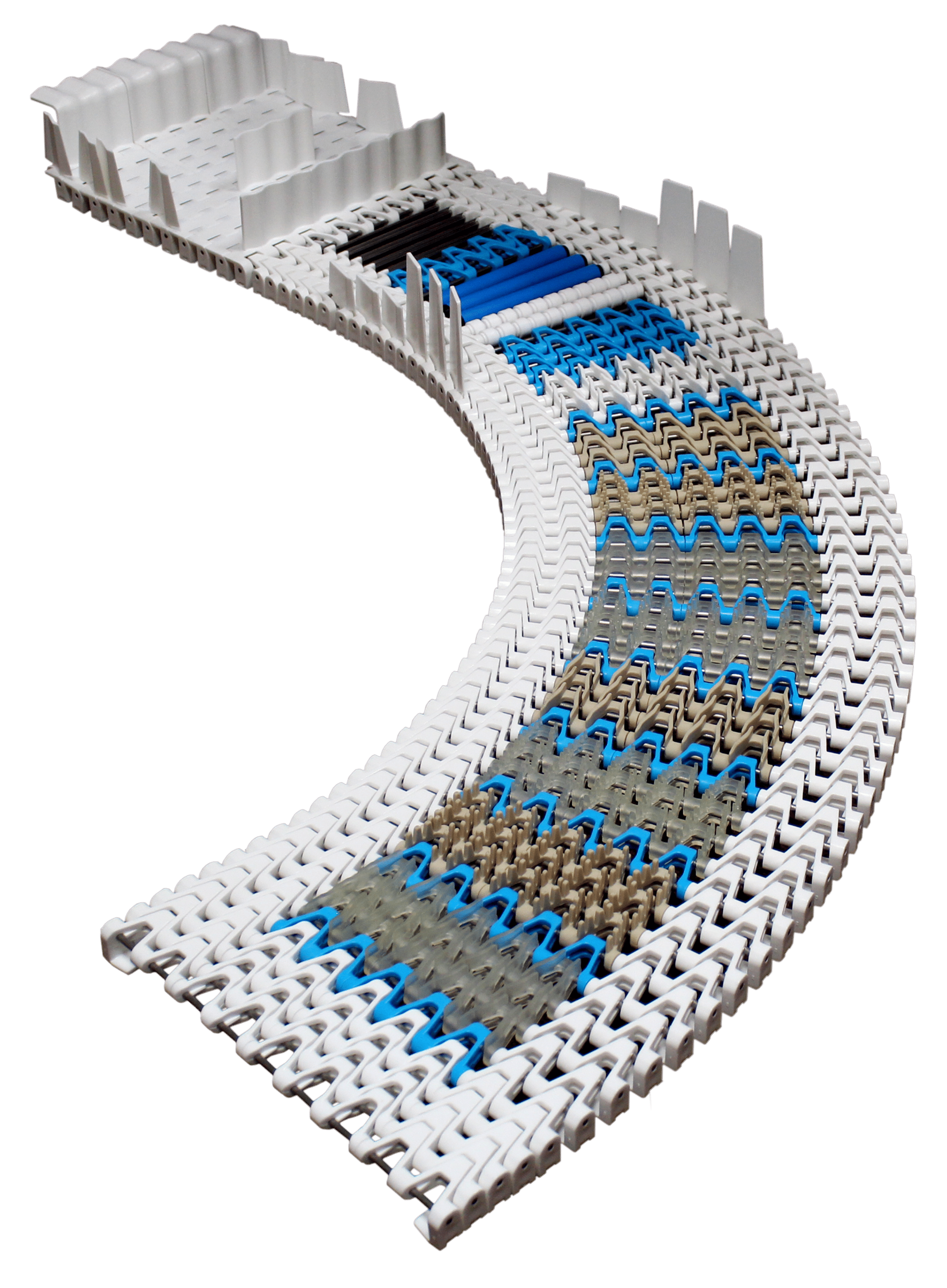

Span Tech has an enormous collection of chain links to choose from. When it comes to building a chain pattern we have over 200 different links and counting! This gives us the advantage of being able to match the chain to the customer’s product specifically for the best results possible.

Plastic Chain Can Go Anywhere

Belt conveyors can only go where they can be stretched between two rollers. This limits them to discrete straight and curved modules. Every time the product has to change direction, a new conveyor is required. This is not the case with modular chain systems. Long runs of conveyor which contain straight sections, horizontal bends, vertical inclines/declines, and even helical curves are all possible in a single conveyor solution – for example, horizontal or vertical offsets.

Repairs are Faster and Easier

Repairing belt conveyors is a time-consuming process. It is costly and leaves the belt with an obvious repair point which could potentially cause issues with products being caught on it. Some belt conveyors cannot be repaired but must be replaced completely which is also quite costly. Modular chain conveyors are incredibly easy to repair. Sometimes they require no special disassembly of the components other than the chain itself. Since there is no tensioner or catenary to deal with, repairing chain links on a modular chain system is incredibly fast and inexpensive.

So the next time you are deciding on a solution to your conveying project, it may be beneficial to give modular plastic chain conveyor belt a second look. Minimize your downtime and increase your throughput with Span Tech Conveyors.