SORTING & MERGING CONVEYORS

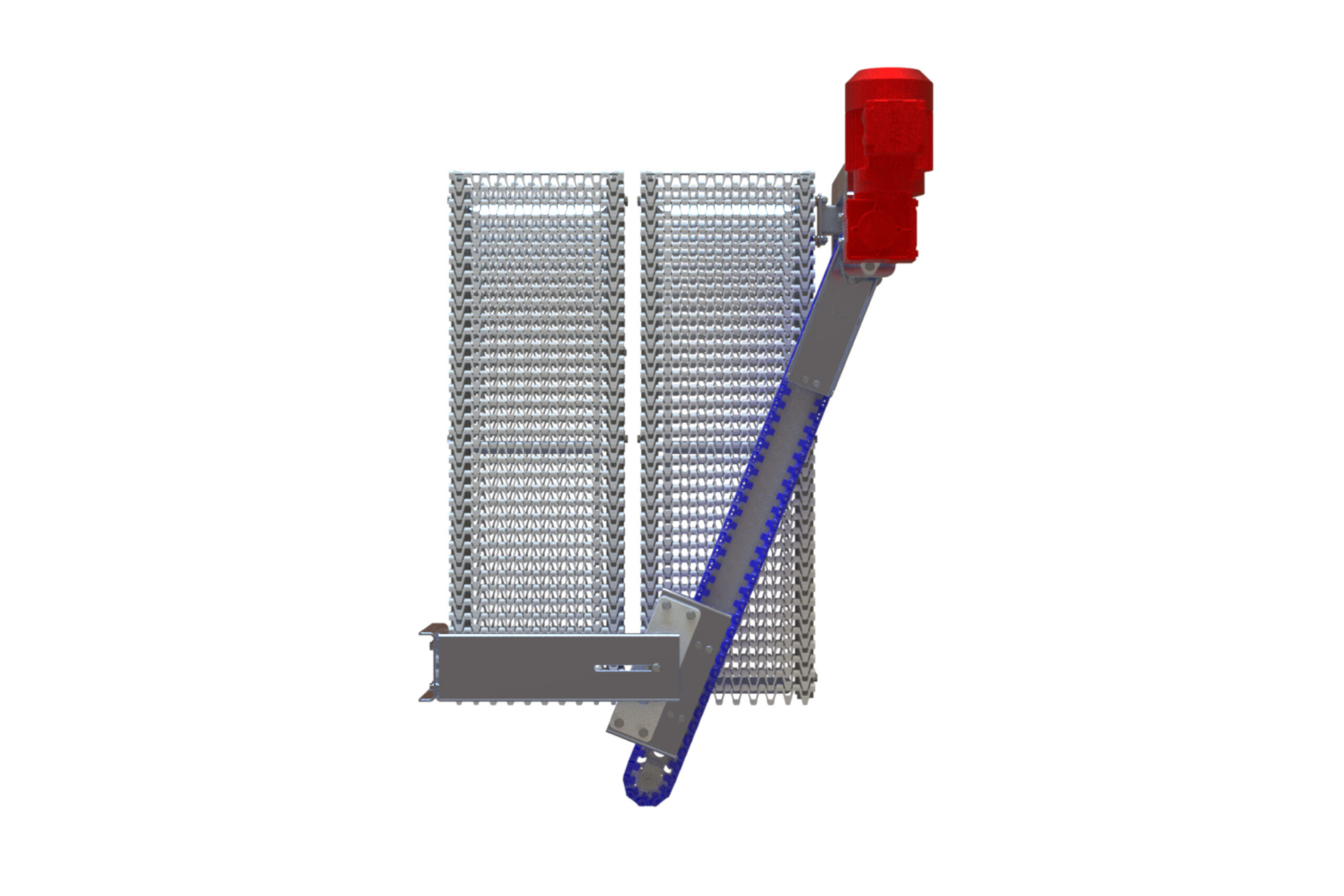

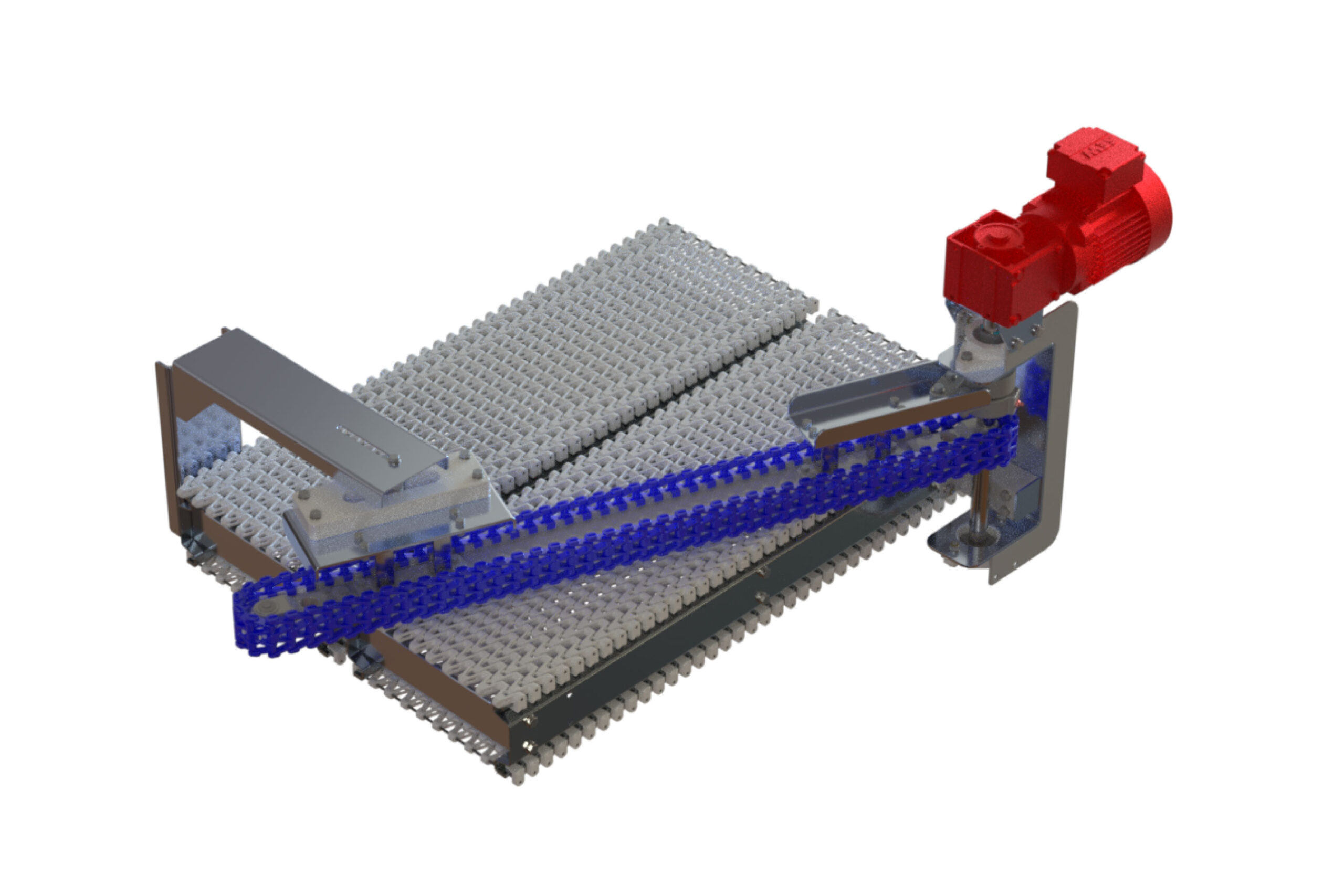

POWERed conveyor diverter arm

Efficient, Precise, and Versatile Product Diverting Solutions

Span Tech’s Powered Divert offers fast, precise, and flexible sorting and diverting, ideal for industries like food, pharmaceuticals, e-commerce, and distribution. It integrates seamlessly into existing conveyor systems, providing a cost-effective solution for managing complex product flows.

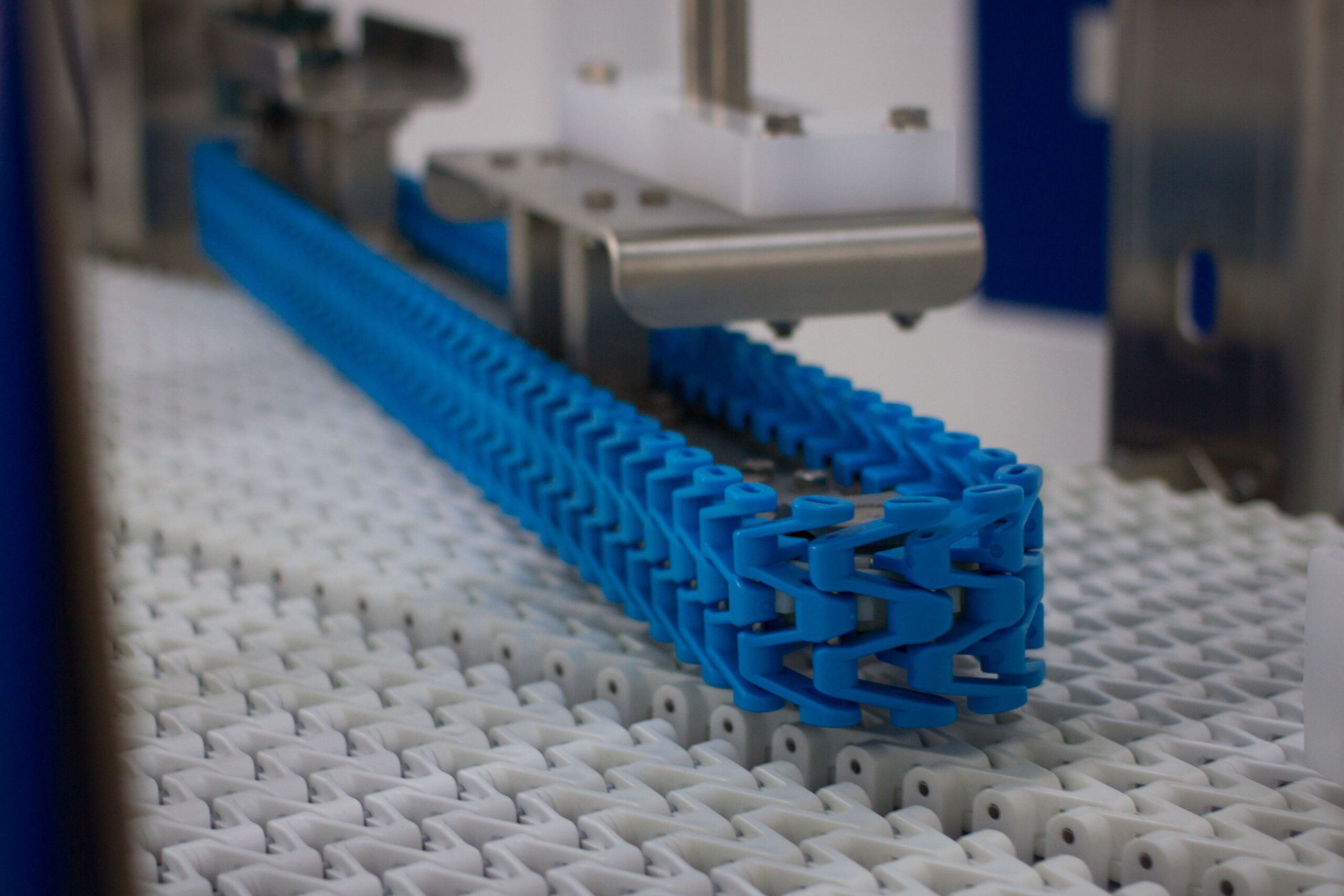

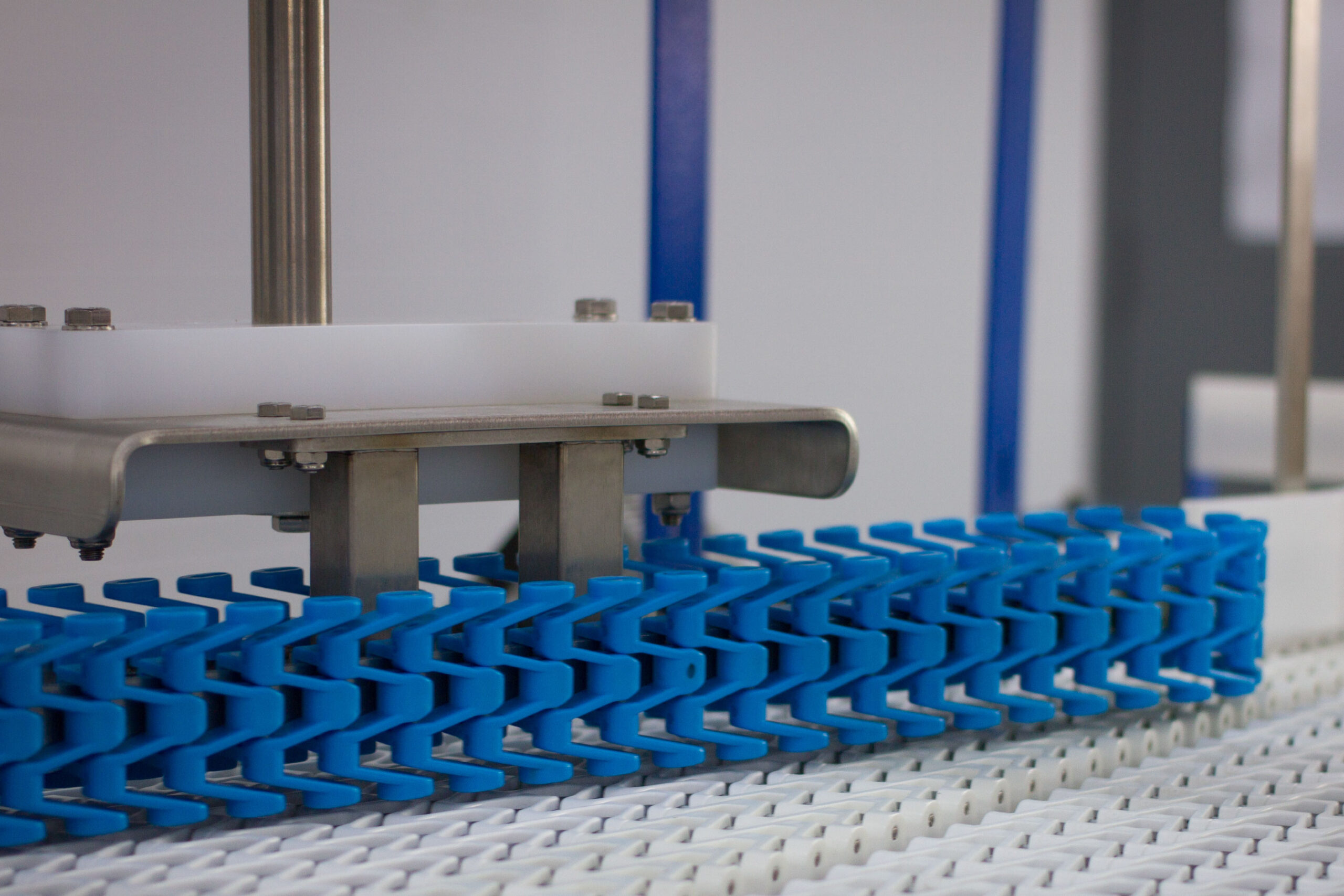

Especially suited for non-rigid items like bagged products, it operates in tight spaces where traditional divert systems wouldn’t fit. The Powered Divert uses a small conveyor turned on its side to act as a powered face plow to keep products moving smoothly, preventing accumulation issues and ensuring efficient product handling.

High-Speed, Precise Diverting

The Powered Divert handles fast-paced, accurate product diverting, efficiently managing a wide range of item types and sizes without sacrificing throughput.

Smooth, Controlled Mechanism

Its powered design ensures smooth, controlled diverting, reducing jams and damage, making it ideal for delicate items like packaged goods and electronics.

Compact, Modular Design

The compact, modular design integrates easily with existing systems, offering flexibility for upgrades or expansions with minimal disruption.

COMMONLY USED IN THESE INDUSTRIES

Streamline Your Product Flow with Powered Precision

The Powered Divert Conveyor is an ideal solution for facilities looking to optimize sorting and routing while maintaining precision and efficiency. Its adaptability, speed, and reliability make it a key component in modern material handling systems.

Applications For Powered Diverts

Food Industry

- Sorting packaged or raw food products into separate lanes for inspection, packaging, or distribution.

- Diverting products like baked goods, frozen foods, or snack bags to designated lines.

Beverage Industry

- Directing bottles, cans, or cartons to filling, labeling, or packing stations.

- High-speed sorting of beverage containers for different production stages.

Pharmaceutical Industry

- Redirecting medications, medical devices, or packaging materials to specific processes or destinations.

- Ensuring precise handling in cleanroom environments.

E-Commerce and Distribution

- Sorting parcels or packages by destination for shipment or storage.

- Managing high-speed sorting lines in fulfillment centers.

Rules of thumb

Features & Benefits

High-Speed, Precision Diverting

The Powered Divert is engineered to handle high-speed product diverting with pinpoint accuracy, making it perfect for fast-paced environments where precise product placement is crucial. Whether diverting light or heavy items, our Powered Divert can efficiently manage a wide range of product types and sizes, ensuring optimal throughput without compromising accuracy.

Smooth, Controlled Diverting Mechanism

The Powered Divert features a unique, powered mechanism that ensures smooth and controlled diverting of products, minimizing the risk of jams, product damage, or misalignment. This smooth operation is especially beneficial for handling delicate items, such as packaged goods, electronics, or fragile products, where gentle handling is essential.

Compact & Modular Design

The compact, modular design of the Powered Divert allows for easy integration with existing conveyor systems. This flexibility ensures a seamless transition with minimal disruption to your operations, making it an excellent choice for system upgrades or expansions.

Videos

Gallery

customizable

Span Tech offers tailored solutions to meet specific operational needs, whether for delicate handling or heavy-duty operations.

Durabile & Efficient

Span Tech conveyors are engineered for durability, built with high-quality materials to withstand tough environments and reduce maintenance costs. Their robust design ensures long-lasting, reliable performance, maximizing uptime and productivity for any operation.

Partnership

OEMs, Distributors, Integrators and End Users, choose Span Tech for innovative and reliable conveyor solutions tailored to unique needs. Our systems offer seamless integration, durability, and reduced maintenance, maximizing ROI and efficiency.

FAQs About Powered Divert Conveyor Systems

Are Powered Diverts Customizable for Specific Industry Needs?

Yes, Powered Divert conveyors are highly customizable. They can be tailored to meet specific operational requirements, including varying belt widths, speeds, and materials. This flexibility allows them to be adapted for different types of products and operational needs, ensuring that they fit seamlessly into existing systems and processes.

What Are the Maintenance Requirements for Powered Divert Conveyors?

Powered Divert conveyors are designed for durability and low maintenance. They typically require less upkeep due to their efficient design and fewer moving parts compared to traditional conveyors. However, regular inspections and routine maintenance are recommended to ensure optimal performance and longevity. This may include checking and adjusting belt tension, lubricating bearings, and inspecting worn parts.

Can Powered Diverts Be Integrated With Existing Conveyor Systems?

Absolutely. Powered Divert conveyors can be seamlessly integrated with existing conveyor systems. Their modular design allows for easy incorporation into current material handling setups. This integration capability ensures that power diverts can enhance existing workflows without the need for extensive modifications or overhauls of current systems.

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

SpanTech’s EZGuide rail system has greatly improved change over times on our bottle filling line. We fill a wide range of bottle sizes and styles. The EZGuide system makes it easier and quicker to adjust between larger and smaller containers. One great feature is the lack of protruding rods from the sides of the conveyors. We are looking at installing this rail system on more filling lines in the near future.

I feel like Span Tech offered us more diversity, custom conveyors, especially for the products that we run and how we run them.

The sales and service personnel at Span Tech are always very professional and helpful throughout the entire process, from design phase, quoting, order processing and delivery of equipment. Quality equipment, professional service and knowledgeable personnel are why Arr-Tech’s choice for conveyor systems will always be Span Tech.

Paradise Tomato Kitchen has used Span Tech conveyors for our sanitary food pouch conveying systems for many years. These sanitary conveyors have provided the best cost of ownership, or the lowest net present value, of any processing conveyors we have used in our food manufacturing plants. These conveyors are easy to widen, lengthen or design for curves and angles to convey our flexible pouches between unit operations.

The quality of this product speaks for itself. Where the difference lies is in the quality of the organization. The whole Span Tech organization – Sales, Engineering, Service – works to serve customers’ needs, not just sell conveyors.