When designing a layout for your production needs, floor space often times becomes a huge issue. Sometimes there just isn’t enough room for everything that you need and other options have to be explored. This is when the ability to elevate product vertically becomes a more logical solution. Span Tech offers many solutions to product elevating while minimizing the footprint within your facility to achieve the most from the floor space you have.

Small Footprint Conveyors

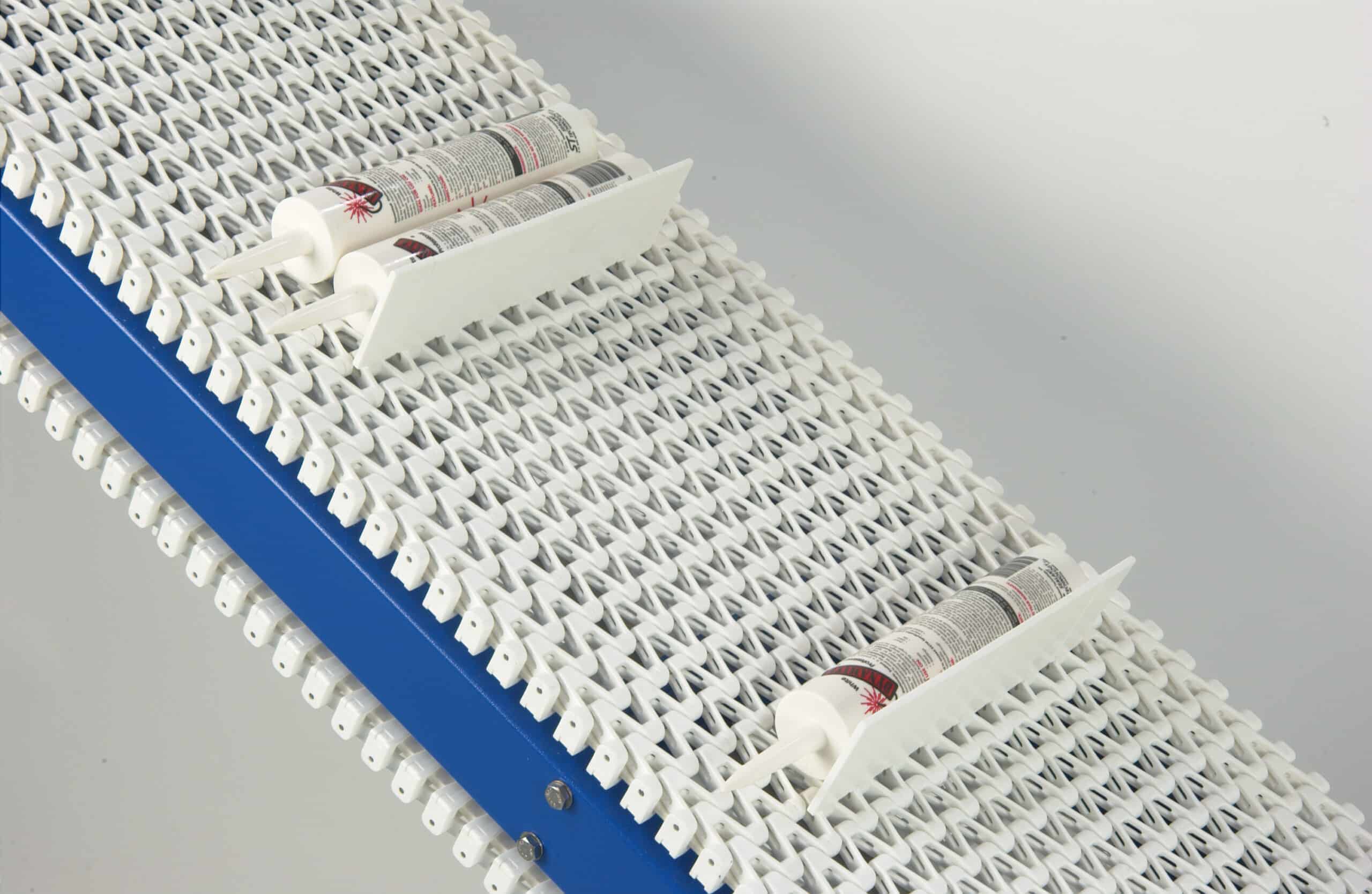

Standard Incline Conveyor

-Biggest Footprint

A standard incline conveyor with plain (non-friction) chain can elevate most products at incline angles of up to 5 degrees successfully . With high friction links, products can incline up to 30 degrees. High friction links include plain santoprene and plain polyurethane, 6mm Brush-Top santoprene and polyurethane, and 10mm Brush-Top santoprene and polyurethane. Plain Cleats and Scoop Cleats can be added to carry products up to 90 degrees straight up. Scoop cleats are used for small products that will fit in the scoop.

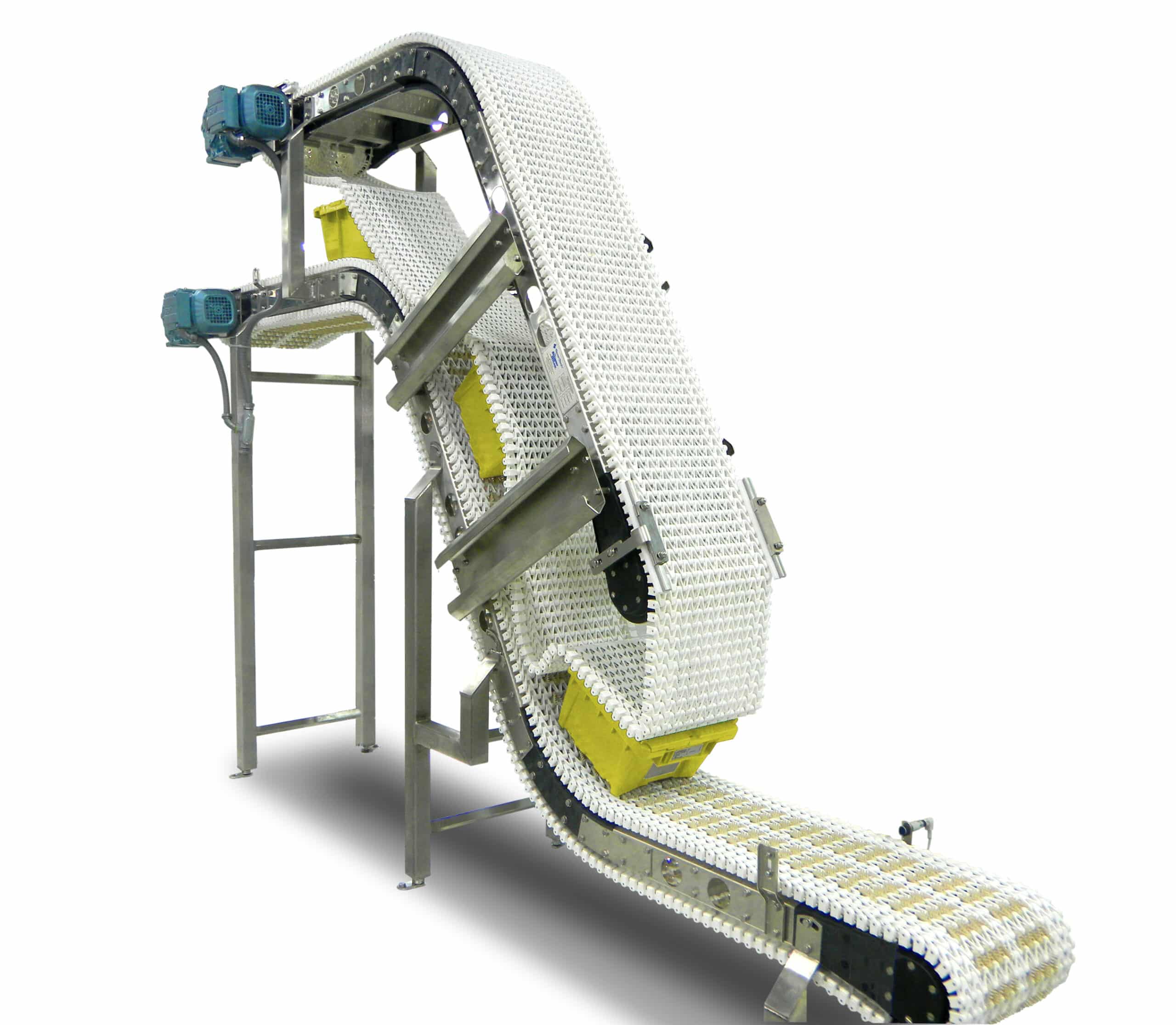

Topper Lift

-Smaller Footprint than Standard Incline

Topper Lifts use two stacked conveyors to incline products up to 70 degrees. High friction chain is used on either or both of the conveyors. A Topper Lift will incline nearly any product regardless of size or shape.

Wedge Unit

-Smaller Footprint than Topper Lift

Wedge Units use two conveyors to squeeze the sides of the product to carry the product vertically. The height of the wedge does not change the footprint of the wedge. We offer two different kinds of wedges; a fixed wedge for one size product only and an adjustable wedge for production runs with different-width products.

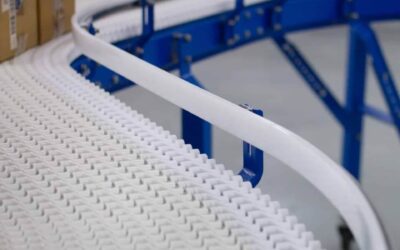

Spiral Elevator

-Smallest Footprint

Depending on the chain width Spiral Elevators can have a larger or smaller footprint than a wedge. The height of the spiral does not affect the footprint of the spiral. Spiral conveyors are not only used for inclining but also for cooling and buffering of products.

All of our Systems are completely customizable to fit your specific needs. Contact Us and together we can figure out the best system to take your ROI to new heights.