What is Goods-to-Person Order Fulfillment?

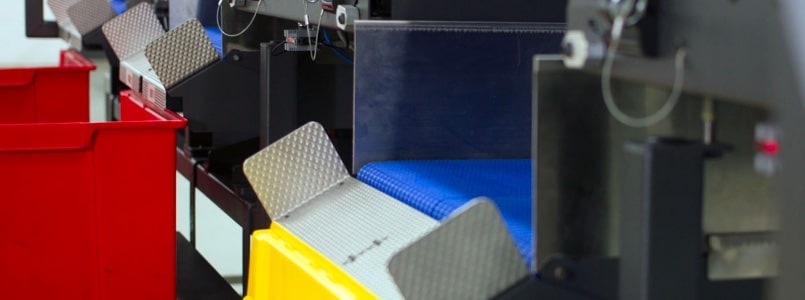

Goods-to-person order fulfillment in a warehouse involves the automatic transportation of products directly to operators as needed. This method combines computerized storage with strategic, ergonomic item picking processes. When a new order must be fulfilled, automated storage and retrieval systems (ASRS) and mobile robots collect goods from their places of storage and deliver them to the appropriate workstation. Depending on the item’s size, that workstation can be a pallet or tote-based system and include horizontal or vertical carousels.

The goods-to-person system is fairly new in the manufacturing and distribution industry compared to the person-to-goods system. As a more traditional approach, person-to-goods order fulfillment consists of employees taking the most efficient paths to manually retrieve necessary items.

Before the days of eCommerce, it was more acceptable for pickers to utilize the goods-to-person system. They would spend a majority of their time traveling throughout a warehouse to locate products and the rest of their time selecting them. In modern times, however, warehouses are storing much more inventory and must meet rising demands for fast deliveries. Goods-to-person systems are proving effective in helping distribution centers address their needs.

Benefits of Goods-to-Person Systems

The goods-to-person process offers a great deal of perks to warehouses and helps give companies a competitive advantage in their industry. Adopting automated picking systems like this can provide the following advantages:

Greater Levels of Productivity

Since goods-to-person order fulfillment runs on automation, it allows your warehouse to run at a greater level of efficiency. Through the use of state-of-the-art technology, your staff will have the ability to meet peak demands and fulfill orders seamlessly.

Improved Accuracy

Automated picking systems help eliminate the risk of errors like selecting the wrong item or sending a product to the wrong location. You’ll avoid spending extra time and money that are required when errors are made, like having to resend products or search for inventory a second time. The fewer mistakes your distribution center makes, the more satisfied your customers will be.

Reduced Labor Needs

In the traditional person-to-goods system, warehouse workers must undergo a great deal of physical labor. From pushing heavy carts to running back and forth with retrieved items, these actions can lead to injuries and worker’s compensation claims. Automated picking systems like goods-to-person help alleviate these demands and can reduce the risk of work injuries as a result.

Increased Sanitation

In the age of social distancing and contactless delivery, a sanitized item picking process is more important than ever. Since the goods-to-person method involves minimal human contact with products, order fulfillment is as germ-free as possible.

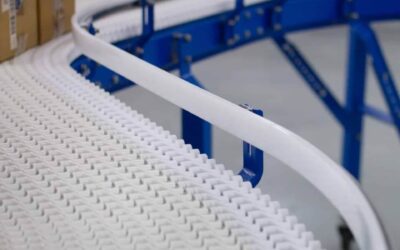

Utilize a Goods-to-Person System with Premium Equipment from Span Tech

If you’re considering goods-to-person order fulfillment for your distribution center, Span Tech is here to assist. Since our founding in 1988, we’ve made it our mission to help your warehouse run as smoothly as possible. Through extensive innovation and testing, our team is committed to providing the best equipment on the market to help your plant run more efficiently than ever before. For top-quality conveyor solutions you can count on, start your estimate today!