What Is Conveyor Belt Tracking?

Conveyor belt tracking is the process of aligning and controlling a conveyor belt so that it follows the desired path. Tracking is a process of adjusting idlers, pulleys and loading conditions to adjust and fix any tendency of the belt to run any way other than intended.

How to Track a Conveyor Belt

Conveyor belt tracking is important but it doesn’t have to be complicated. Here are three easy steps for tracking a conveyor belt.

- While the conveyor is operating, loosen the bolts closest to the tail pulley. That will loosen the primary method of steering the conveyor belt, the snub roller.

- Using a rubber mallet, gently tap the bolts in whatever direction you want the conveyor belt to move. This will cause the snub roller to move. After the snub roller has been adjusted, be sure to re-tighten the bolts so it will be locked into the new position.

- Steps 1 and 2 should be repeated until the center of your conveyor belt is within a quarter inch of the tail pulley’s center. Be careful not to make any large adjustments. A small adjustment can make a huge change. Make sure to start with the snub rollers closest to the ends of the conveyor and work your way towards the center.

How to Fix Conveyor Belt Tracking

When tracking conveyor belts, there are steps you can take to maintain your conveyor belts as well as steps you should take when there are issues with conveyor tracking. The following tips are things to watch for if you are having trouble with conveyor belt alignment.

Make Sure The Conveyor Frame Is Level and Square

A large percentage of conveyor belt tracking issues are caused by the track being out of level or square. If your conveyor is out of level or square, the belt will move to one side or the other.

Using a standard level, you can quickly check your conveyor system’s levelness. It’s important to check both the pulleys and the frames for levelness. To check that your conveyor bed is square, snap dimensions from one corner to the opposite corner on each side of the conveyor belt. The measurements should be equal. If they are not, squaring rods on the bottom of the conveyor can be used to pull the frame into alignment.

Confirm the End Pulleys Are Square

Sometimes conveyor belt installers will steer the end pulley to track the conveyor belt. Unfortunately, this can make the problem worse. Instead, use the snub rollers or idlers to track the belt, as intended.

Check for Any Debris in Your System

It’s important to inspect conveyor belts for not just mechanical issues, but also cleanliness. If tape or other debris builds up on one or both of the end pulleys, it can lead to a crown or a raised portion on the pulley. This will result in problems with conveyor belt tracking.

Ensure Your Conveyor Belt Has Been Cut Straight

Problems with your conveyor tracking may be a result of manufacturing defects. During the manufacturing process, the belts can be cut improperly leaving a curvature or arc. If you have reason to think this may be the problem, remove the belt and lay it out flat to see if it looks straight.

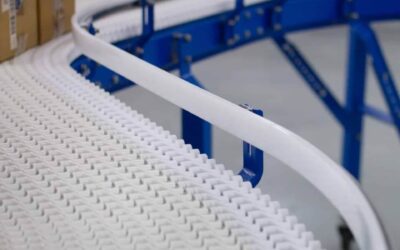

Let Span Tech Guide Your Conveyor Belt System

Now that you’ve read our guide to conveyor belt tracking, take a look at our products and see how Span Tech can help you. If you use conveyor belts to make your business go, our new line of EZSpan conveyors can help. With their modular chain design, conveyor belt tracking is no longer an issue. Contact us today to find out more about how we can help.