What Is Warehouse Safety?

Warehouse safety rules are the guidelines and best practices that help ensure a safe environment for workers and reinforce safe behavior. The health and safety of your employees must be a high priority for your business.

8 Ways to Promote Conveyor Safety Standards in Your Warehouse

Your company likely has conveyor safety standards in place, but are you doing everything you can to make sure that your managers and employees know and follow those standards?

Below, we are highlighting eight simple steps your company can take to help promote warehouse conveyor safety standards in your facility.

1. Train Employees on Conveyor Safety Standards

Conveyor safety training is one of the easiest and best ways to promote warehouse rules and standards. Any employees who work around or on the conveyor system must be trained in conveyor safety rules and procedures. Topics covered during training should include the following:

- How to safely operate the conveyor system

- What to do in the event of an emergency

- What to wear (and not wear) when working on a conveyor

2. Install Safety Signs and Warnings Throughout Your Facility

All potential hazards must be clearly marked with warnings and signs placed in locations where they can easily be seen. Also, all warehouse safety rules and procedures should be included on signs to remind your employees of the best ways to reduce accidents and avoid injuries.

3. Regularly Inspect and Maintain Your Conveyor Systems and Facility

Regular safety inspections of your conveyor system, conducted by a qualified technician, are important to maintain conveyor safety standards and keep all your warehouse employees safe. All belts, motors, pulleys and other moving components of your conveyor system should be inspected. Any damaged parts must be fixed or replaced as quickly as possible.

Regular cleaning of your conveyor system is also important, as it removes dirt and debris that can affect performance and create a safety hazard.

4. Keep Your Facility Clean and Organized

Allowing your warehouse to become cluttered and messy creates a safety issue, especially if there is clutter or mess near any moving conveyor systems. Managing inventory and ensuring walkways and exit routes are clear of clutter and mess will go a long way toward promoting warehouse safety.

5. Encourage Employees to Report Potential Hazards

Your employees should be told to report all potential safety hazards they see or become aware of, so the issues can be fixed before someone gets hurt.

6. Form A Safety Committee

Pull members from various departments to work together to brainstorm ideas for making your warehouse a safer place and to promote safety measures among the other employees.

7. Keep Records

Every warehouse and conveyor system should undergo regular inspections and maintenance. Records tracking those actions must be kept to ensure conveyor safety standards are being met.

8. Choose the Right Conveyor Systems for Your Facility

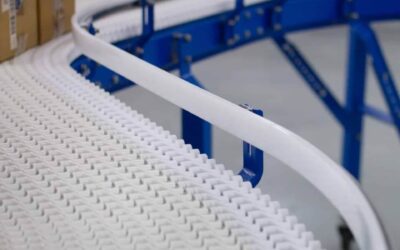

The conveyor you choose for your warehouse must be appropriate for the type of work you will be doing and the materials you’ll be moving on the conveyor system. You must also account for the size and layout of your facility to make sure the conveyor system fits safely and allows workers to move around.

Depending on the size and layout of your facility, you may need standard conveyors, a curve conveyor or a straight conveyor to safely move materials around your facility.

Trust Span Tech For All Your Conveyor Needs

Now that you know about warehouse conveyor safety standards, you may be ready to add a conveyor line. If you have questions or want to find out more about conveyor systems and how to use them safely, Span Tech can help. Contact us today and find out how.