Industries

BEVERAGE CONVEYORS

The Ultimate Solution for the Food Industry

In the beverage industry, efficiency, hygiene, and reliability are critical to maintaining a smooth and productive operation. Span Tech Conveyors are expertly designed to meet the unique challenges of beverage production, offering solutions that enhance productivity, ensure product safety, and streamline processes. Whether you’re bottling, canning, or packaging beverages, Span Tech provides conveyor systems that are perfectly suited to the rigorous demands of the industry.

Why Choose Span Tech Conveyors for the Beverage Industry?

- Fast & Efficient Handling – Designed for high speed bottling, canning and packaging without jams or misalignment.

- Sanitary & Washdown Ready – Corrosion resistant materials withstand frequent cleaning and wet environments.

- Smooth & Gentle Transport – No tipping, no spillage, even at high speeds.

- Customizable for any layout – Handles straight runs, curves, inclines and declines to maximize floor space.

- Reliable & Low Maintenance – Modular chain design eliminates tracking issues and reduces downtime.

Where Our Conveyors Excel in Integration

Filling Stations |

Capping and Sealing Machines |

Labeling and Coding Machines |

|

Liquid fillers Multi product fillers |

Automated cappin stations Heat sealing units |

Print and apply systems Laser etching or inject coding |

Inspection Systems |

Case Packing and Cartoning |

Palletizing Stations |

|

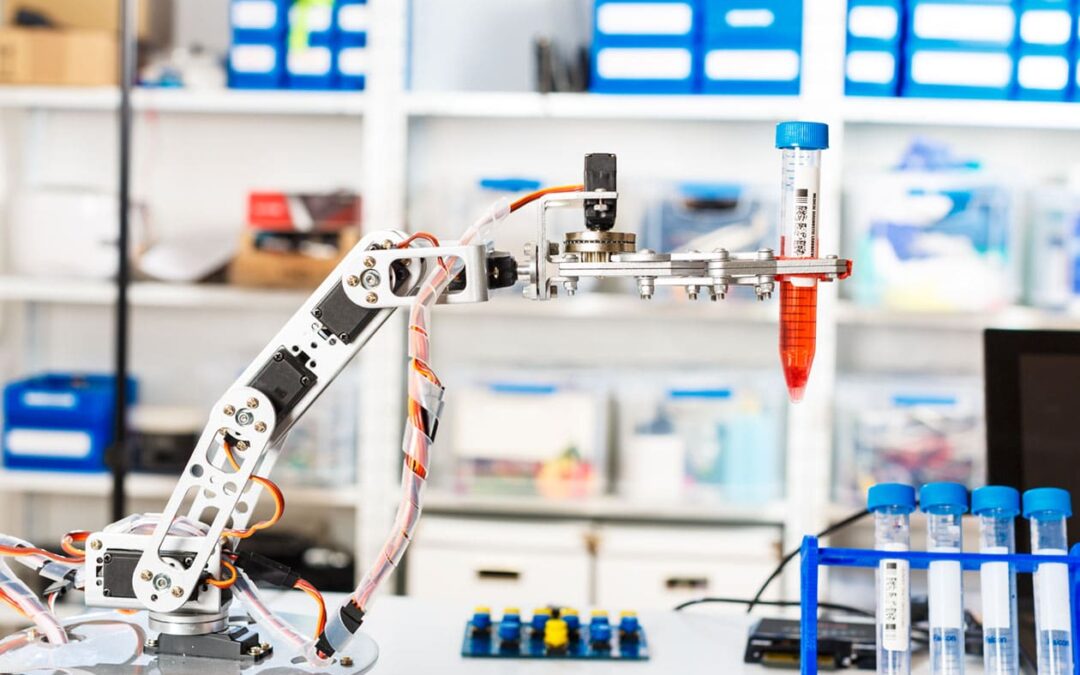

Metal detectors Xray Machines Vision systems |

Robotic case packers Cartoners |

Robotic or conventional palletizers |

Accumulation and Buffer Zones |

Specialty Workstations |

|

|

Accumulation tables Staging conveyors |

Mixing stations Secondary Packaging |

With conveying and manufacturing experience in all phases of beverage production – from brewing to bottling to packaging and distribution – Span Tech’s innovative conveyor systems are a perfect match for beverage producers.

THE FEATURES & BENEFITS

GENTLE PRODUCT HANDLING

Engineered for smooth operation, our conveyors prevent spills and damage, using features like small transfer gaps and controlled speeds to maintain product integrity.

HIGH SPEED EFFICIENCY

Engineered for fast, consistent operation, these conveyors maintain precision and safety at high speeds, reducing jams and misalignment.

HYGEINIC DESIGNS

Built with food-grade materials, Span Tech Conveyors feature stainless steel and open designs for easy cleaning, meeting strict food and beverage safety standards.

VERSATILE SOLUTIONS

Customizable for a variety of containers and packaging formats, our conveyors handle tasks from filling to palletizing, adapting to your specific needs.

%

ON TIME SHIP RATE

FAQs About Custom Conveyors Used in the beverage industry

Why are Span Tech conveyors a great choice for the beverage industry?

Span Tech conveyors are an ideal solution for the beverage industry due to their versatility, ability to handle various container types, and durability in high-speed, high-volume environments. They are designed to minimize downtime and maintain continuous production flow, which is critical in beverage manufacturing.

Are Span Tech conveyors suitable for both empty and filled beverage containers?

Absolutely. Span Tech conveyors are engineered to handle both empty and filled containers with precision. Whether you need to transport lightweight empty bottles or fully filled, containers, these conveyors maintain stability and control throughout the process.

How does Span Tech address hygiene and sanitation concerns in beverage production?

Sanitation is critical in the beverage industry, and Span Tech conveyors are designed with this in mind. The conveyors feature easy-to-clean surfaces, modular components for quick disassembly, and chain washdown add-ons to ensure the equipment meets stringent hygiene standards.

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

SpanTech’s EZGuide rail system has greatly improved change over times on our bottle filling line. We fill a wide range of bottle sizes and styles. The EZGuide system makes it easier and quicker to adjust between larger and smaller containers. One great feature is the lack of protruding rods from the sides of the conveyors. We are looking at installing this rail system on more filling lines in the near future.

I feel like Span Tech offered us more diversity, custom conveyors, especially for the products that we run and how we run them.

The sales and service personnel at Span Tech are always very professional and helpful throughout the entire process, from design phase, quoting, order processing and delivery of equipment. Quality equipment, professional service and knowledgeable personnel are why Arr-Tech’s choice for conveyor systems will always be Span Tech.

Paradise Tomato Kitchen has used Span Tech conveyors for our sanitary food pouch conveying systems for many years. These sanitary conveyors have provided the best cost of ownership, or the lowest net present value, of any processing conveyors we have used in our food manufacturing plants. These conveyors are easy to widen, lengthen or design for curves and angles to convey our flexible pouches between unit operations.

The quality of this product speaks for itself. Where the difference lies is in the quality of the organization. The whole Span Tech organization – Sales, Engineering, Service – works to serve customers’ needs, not just sell conveyors.

customizable

Span Tech offers tailored solutions to meet specific operational needs, whether for delicate handling or heavy-duty operations.

Durabile & Efficient

Span Tech conveyors are engineered for durability, built with high-quality materials to withstand tough environments and reduce maintenance costs. Their robust design ensures long-lasting, reliable performance, maximizing uptime and productivity for any operation.

Partnership

OEMs, Distributors, Integrators and End Users, choose Span Tech for innovative and reliable conveyor solutions tailored to unique needs. Our systems offer seamless integration, durability, and reduced maintenance, maximizing ROI and efficiency.