Industries

MANUFACTURING CONVEYORS

The Perfect Conveyors for the Manufacturing Industry

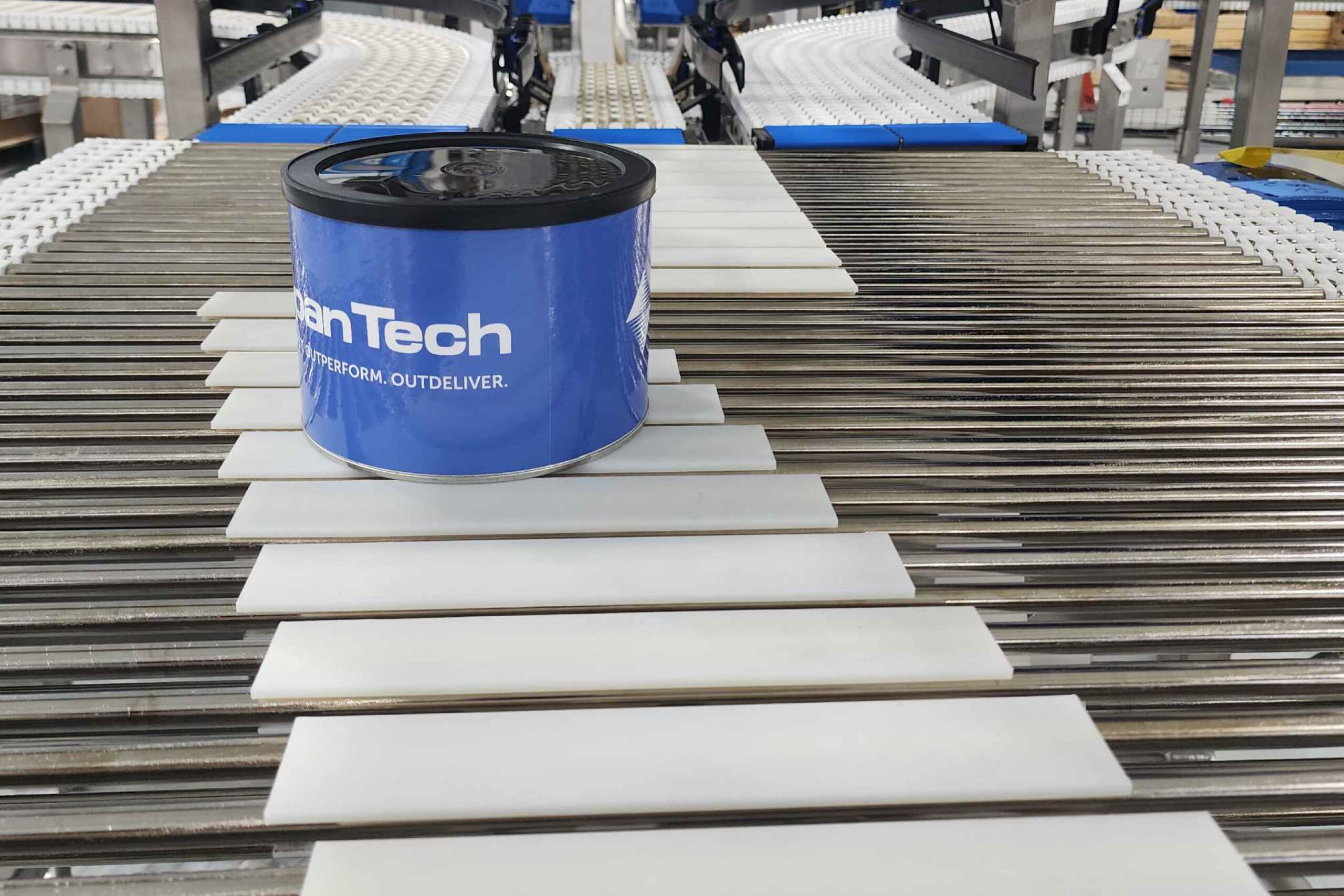

In today’s fast-paced manufacturing environment, efficiency, reliability, and versatility are essential. Span Tech Conveyors are designed to meet the rigorous demands of the manufacturing industry, providing innovative solutions that streamline operations, enhance productivity, and ensure product integrity. From handling delicate components to transporting heavy materials, Span Tech’s range of conveyor systems are tailored to fit the unique needs of manufacturing processes across various sectors.

Why Choose Span Tech Conveyors for Your Manufacturing Needs?

- Easy Integration & Customization: SpanTech produces and supplies easy-to-integrate custom conveyor solutions, which can be modified or redesigned at any point in the future based on your company’s needs.

- Scalable Solutions for Any Business Size: Small or large, consumer goods manufacturers and distributors around the world depend on our material handling solutions to enhance productivity and efficiency.

- Boost Productivity & Reduce Downtime: With high-quality custom solutions, exceptional after-sales support, and short delivery and production ramp-up times, Span Tech’s conveyors are designed to:

- Increase system uptime

- Improve line output

- Meet changing market demands

Where Our Conveyors Excel in Integration

Raw Material Handling |

Assembly Lines |

Processing Equipment |

|

Hoppers and bins Mixing machines Cutting or shearing stations |

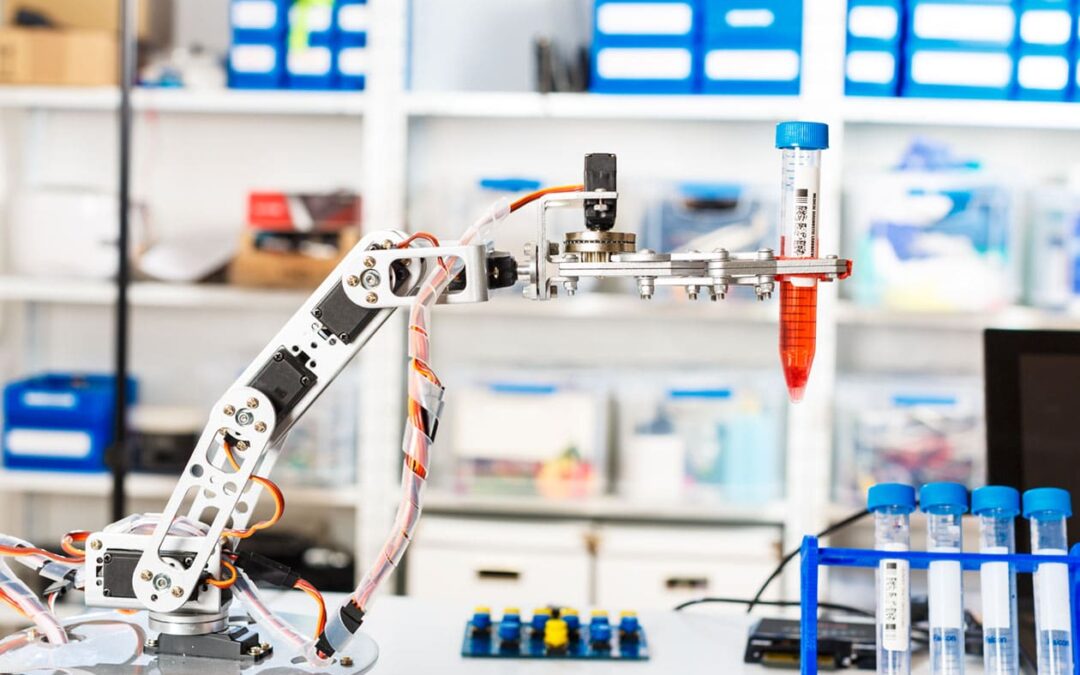

Workstations for manual assembly Robotic assembly stations |

Molding machines Welding and soldering stations Machining stations |

Inspection and Quality Control |

Painting and Coating Systems |

Packaging and Palletizing |

|

Vision systems Weighing stations Non destructive testing equipment |

Spray booths or powder coating stations Drying ovens |

Cartoning machines Stretch wrapping systems Robotic palletizers |

Buffer and Accumulation Zones |

Storage and Retrieval Systems |

Shipping and Distribution |

|

Buffer conveyors Accumulation tables |

Automated storage systems Vertical Lift Modules (VLMs) |

Loading docks Sorting systems |

Span Tech is a leader in conveyor innovation, with a proven track record of delivering high-quality, reliable systems that meet the needs of the manufacturing industry. Our commitment to quality, customization, and customer satisfaction make us the ideal partner for manufacturers looking to enhance their production capabilities.

THE FEATURES & BENEFITS

PRECISION & ACCURACY

Span Tech Conveyors ensure smooth, accurate product movement without misalignment, damage, or delays. For gentle handling or precise reorientation using Twist or Curved Conveyors, our systems uphold the highest accuracy standards throughout production.

COST EFFECTIVE OPERATIONS

By enhancing product flow, reducing maintenance, and optimizing space, Span Tech Conveyors help lower operational costs. Their energy-efficient design and quick ROI make them a smart investment for manufacturers.

DURABLE CONSTRUCTION

Built with high-quality materials, our conveyors are designed to withstand demanding environments. The durable construction minimizes downtime and maintenance, ensuring long-term reliability for high-volume operations.

UNMATCHED VERSATILITY

Span Tech Conveyors handle a range of product sizes, from small, delicate components to large, bulky items. With adjustable widths, variable speeds, and multiple configurations (straight, curved, spiral), our systems can be customized to fit any manufacturing need.

%

ON TIME SHIP RATE

FAQs About Custom Conveyors Used in Manufacturing

Why are Span Tech conveyors ideal for the manufacturing industry?

Span Tech conveyors are designed to meet the diverse needs of the manufacturing industry, offering customizable solutions for a variety of product types, sizes, and manufacturing processes. They are durable, efficient, and adaptable, making them suitable for high-speed, high-volume production environments.

How do Span Tech conveyors improve manufacturing efficiency?

Span Tech conveyors improve manufacturing efficiency by offering smooth, uninterrupted product flow, reducing bottlenecks, and allowing for better production line organization. Their ability to integrate with automated systems and customizable features ensures that they streamline operations and maximize throughput.

Can Span Tech conveyors handle a variety of products in a manufacturing line?

Yes, Span Tech conveyors are versatile enough to handle a wide range of products, from small, precision parts to large, bulky items. This makes them ideal for manufacturers who deal with varied product lines or have frequent changeovers in production.

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

SpanTech’s EZGuide rail system has greatly improved change over times on our bottle filling line. We fill a wide range of bottle sizes and styles. The EZGuide system makes it easier and quicker to adjust between larger and smaller containers. One great feature is the lack of protruding rods from the sides of the conveyors. We are looking at installing this rail system on more filling lines in the near future.

I feel like Span Tech offered us more diversity, custom conveyors, especially for the products that we run and how we run them.

The sales and service personnel at Span Tech are always very professional and helpful throughout the entire process, from design phase, quoting, order processing and delivery of equipment. Quality equipment, professional service and knowledgeable personnel are why Arr-Tech’s choice for conveyor systems will always be Span Tech.

Paradise Tomato Kitchen has used Span Tech conveyors for our sanitary food pouch conveying systems for many years. These sanitary conveyors have provided the best cost of ownership, or the lowest net present value, of any processing conveyors we have used in our food manufacturing plants. These conveyors are easy to widen, lengthen or design for curves and angles to convey our flexible pouches between unit operations.

The quality of this product speaks for itself. Where the difference lies is in the quality of the organization. The whole Span Tech organization – Sales, Engineering, Service – works to serve customers’ needs, not just sell conveyors.

customizable

Span Tech offers tailored solutions to meet specific operational needs, whether for delicate handling or heavy-duty operations.

Durabile & Efficient

Span Tech conveyors are engineered for durability, built with high-quality materials to withstand tough environments and reduce maintenance costs. Their robust design ensures long-lasting, reliable performance, maximizing uptime and productivity for any operation.

Partnership

OEMs, Distributors, Integrators and End Users, choose Span Tech for innovative and reliable conveyor solutions tailored to unique needs. Our systems offer seamless integration, durability, and reduced maintenance, maximizing ROI and efficiency.