In the pharmaceutical industry, precision, hygiene, and reliability are paramount to ensuring product safety, compliance, and efficiency. Span Tech Conveyors are expertly designed to meet the stringent demands of pharmaceutical manufacturing, offering solutions that enhance productivity, maintain strict hygiene standards, and provide precise handling of delicate products. Whether you’re producing medications, medical devices, or other pharmaceutical products, Span Tech provides conveyor systems that are perfectly suited to the unique challenges of this industry

Why Choose Span Tech for Retail and Ecommerce Conveyors?

- Sanitary & Washdown Ready – Smooth, non porous surfaces prevent bacteria buildup and allow for easy cleaning.

- Precise & Contamination Free Handling – Ensures accurate gentle transport for delicate pills, vials and blister packs.

- Customizable for Cleanroom Applications – Built with low friction, dust resistant materials for aseptic environments.

- No Product Jams – Modular chain design eliminates gaps, ensuring continuous product flow without disruptions.

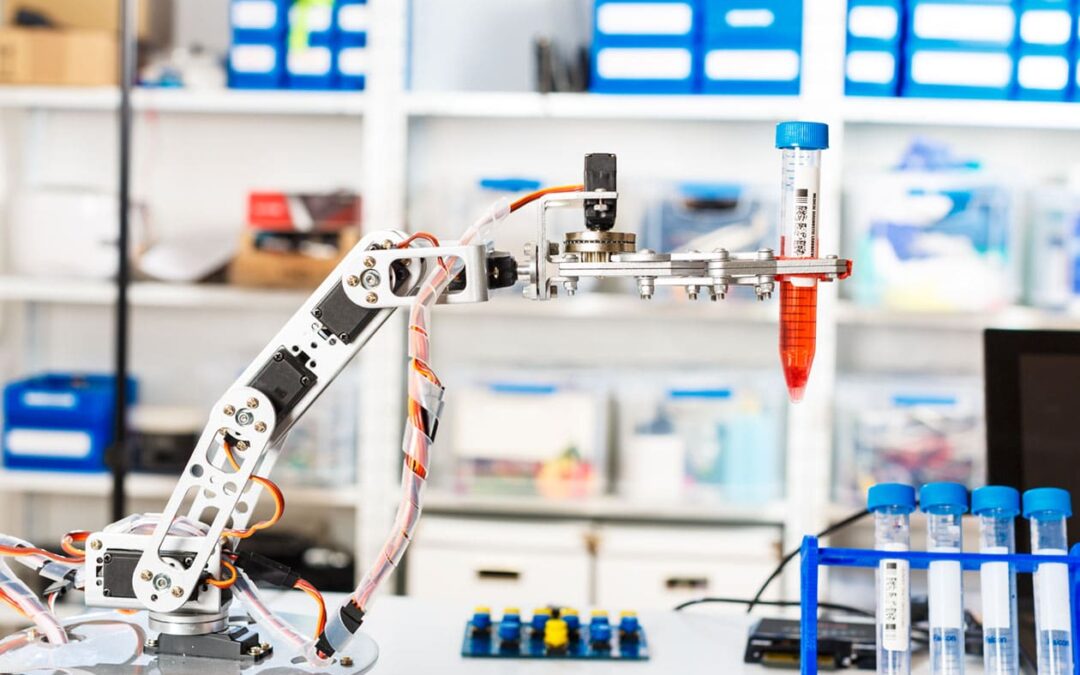

- Automation Ready – Seamlessly integrates with robotic arms, sorting systems and inspection stations.

- Compact & Flexible Layouts – Easily adapts to tight spaces, inclines, declines and curves, maximizing floor space.

Where Our Conveyors Excel in Integration

Filling Stations |

Capping and Sealing Machines |

Inspection and Quality Control |

|

Liquid fillers Powder fillers Blister pack fillers |

Vial capping stations Sealing machines |

Vision systems Checkweighers Metal detectors and Xray machines |

Labeling and Serialization Machines |

Packaging Equipment |

Mixing and Blending Stations |

|

Print and apply labelers Serialization systems |

Cartoning machines Pouch packaging systems Shrink wrapping |

Infeed and discharge for mixing or blending stations |

Secondary Packaging Stations |

Sterillization and Cleaning Stations |

Buffer and Accumulation Zones |

|

Case packers Palletizers |

Moving products through sterilization chambers Transporting equipment that requires cleaning |

Accumulation tables Buffer conveyors |

Span Tech is a leader in conveyor innovation, offering high-quality solutions that enhance productivity, efficiency, and reliability in the pharmaceutical industry. Our conveyors are specifically designed to meet the unique challenges of pharmaceutical production, providing systems that ensure smooth, safe, and compliant operations.

THE FEATURES & BENEFITS

PRECISION HANDLING

Engineered for gentle, accurate movement, our conveyors minimize spills, breakage, and cross-contamination, using small transfer gaps and controlled speeds for careful product handling.

OPTIMIZED FACILITY LAYOUTS

Compact designs optimize floor space, using spirals and curves to maximize vertical and horizontal capacity, ideal for space-constrained facilities.

HYGEINIC DESIGN

Built with pharmaceutical-grade materials, Span Tech Conveyors feature stainless steel, smooth surfaces, and easy-to-clean designs, meeting GMP and FDA standards to prevent contamination.

SEAMLESS INTEGRATIONS

Modular conveyors easily connect with existing equipment, ensuring smooth, cohesive operations through all production stages.

%

ON TIME SHIP RATE

FAQs About Custom Conveyors Used in Pharmaceuticals

Why are Span Tech conveyors a good fit for the pharmaceutical industry?

Span Tech conveyors are ideal for the pharmaceutical industry due to their precision, hygienic design, and ability to handle delicate and small products. These conveyors meet strict FDA and pharmaceutical-grade standards, ensuring the safe and reliable handling of medications and medical products.

Can Span Tech conveyors handle small and delicate pharmaceutical products?

How do Span Tech conveyors support the pharmaceutical industry's stringent hygiene standards?

customizable

Span Tech offers tailored solutions to meet specific operational needs, whether for delicate handling or heavy-duty operations.

Durabile & Efficient

Span Tech conveyors are engineered for durability, built with high-quality materials to withstand tough environments and reduce maintenance costs. Their robust design ensures long-lasting, reliable performance, maximizing uptime and productivity for any operation.

Partnership

OEMs, Distributors, Integrators and End Users, choose Span Tech for innovative and reliable conveyor solutions tailored to unique needs. Our systems offer seamless integration, durability, and reduced maintenance, maximizing ROI and efficiency.