Quality is important to us, because our customers are important to us. As is generally the case with any organization, our customers are the single most important part of our business, without them we wouldn’t exist.

Customers expect you to deliver quality products and services. We work to continuously improve our understanding of their requirements and expectations and provide them with the highest quality products and services that are defect/error free. We strive to provide for our customers in a way that not only meets their expectations, but far exceeds them. By doing this, we help to maintain customer satisfaction and retain their loyalty so they will continue to do business with us in the future. By building a strong reputation for quality and creating these long term relationships with our customers, Quality makes an important contribution to long term revenue and profitability.

An effective Quality program can help keep costs down while poor quality can increase costs. If an effective program is not in place, costs can be incurred from analyzing nonconforming products or services to determine the root causes of failure or defects. Increased costs can also come from having to rework or repair defective products, by scrapping material and using extra material, labor and the associated shipping costs to fix issues. Even higher costs can be incurred if customer service trips on-site are required to fix or replace faulty products. But, the highest cost in many cases would be losing the faith or trust of a customer or multiple customers due to poor quality, so creating and managing a strong quality program is crucial to helping our customers and us be successful.

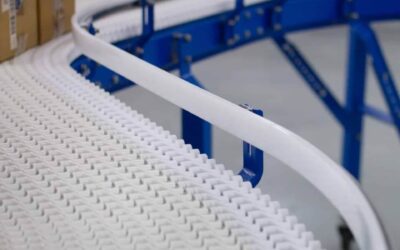

This video shows some of the innovations that make up our quality products.

At Span Tech, our quality program is a dynamic system that is primarily customer focused (both external and internal) and is designed with an emphasis on prevention. Some of the principals we use are;

- Customer Focus

- Leadership

- Training – Developing employee skills and abilities

- Manufacturing capability and the appropriate application of technology

- Supplier performance and conformance

- Continual process improvement – productivity and efficiency

We all see quality as a shared responsibility. We believe that quality applies to every department and every employee in everything we do. Our goal is to build in quality rather than attempting to inspect defects and errors out.

Read some of our customers testimonials here.

If you enjoyed this post and want to stay up to date with all of our innovations then CLICK HERE and Subscribe to our Newsletter and get all of our stories delivered straight to your inbox!!