A Closer Look at the New EZ Guide Rail System

Popular in the packaging and distribution industries, conveyor guide rails are required when accumulating products to prevent the products from walking off the conveyor. As the latest conveyor guide rail design to hit the market, Span Tech’s EZ Guide Rail System can solve many of the primary issues that traditional guide rail systems have.

Carefully designed by our team of expert engineers, it’s sure to make your manufacturing process more efficient than ever before.

Unique Product Features

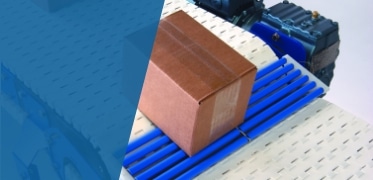

Conveyor guide rails play a crucial role in keeping your product in line and secure during transport. From directing products to a certain position to transferring them from one conveyor to another, these systems have a lot of functions.

Span Tech’s new EZ Conveyor Guide Rails take these features to the next level. Our latest product has notable benefits that set it apart from other guide rails on the market.

No Protruding Conveyor Guide Rail Brackets or Shafts

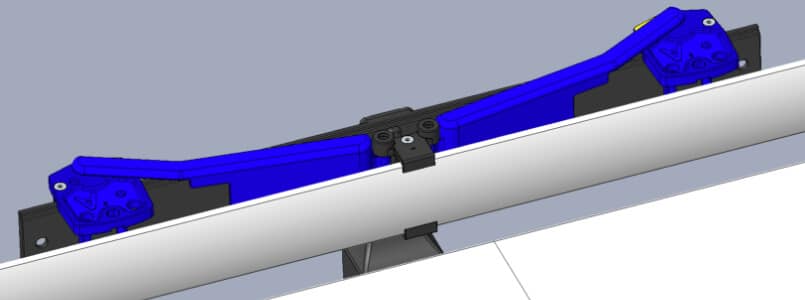

Traditional conveyor guide rail systems tend to use a solid-mounted shaft to mount their guide rail. This can be a major safety hazard. Why? When the rail is adjusted to its “maximum open” position, the shafts will stick out from the conveyor’s sides. This makes it easy for people to get their clothes or body parts caught and can cause injuries on the job.

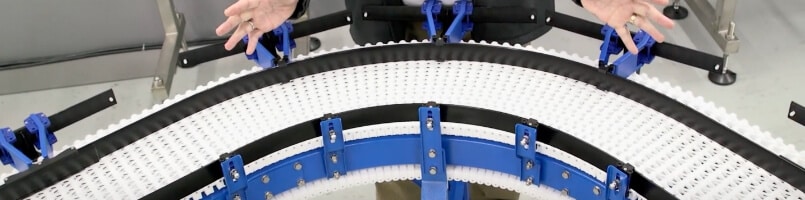

In comparison, our EZ Guide System doesn’t contain protruding brackets or shafts. You won’t find mechanical components sticking out from the sides of the conveyor during an adjustment. Instead, all the mechanics take place within the shrouded portion of the system. This keeps everything safe for anyone walking close to the conveyors.

Designed to Remain Adjustable Through Curves

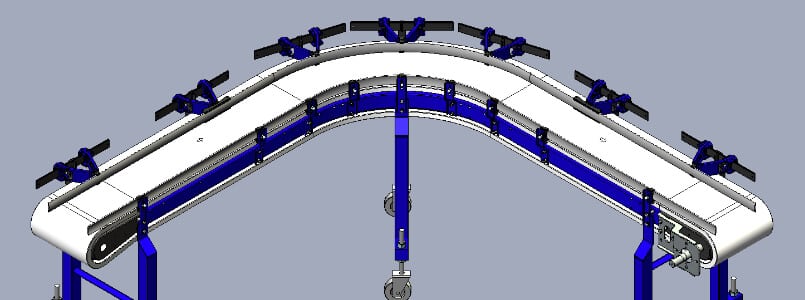

While many of the traditional guide rail systems can be made to adjust their width in straight sections, few can be adjusted through a curved portion of a conveyor. Why? The radius of a section is simply too difficult for them. To adjust through a curved portion, guides must bend and their length has to increase or decrease as the radius is changed.

Our EZ Guide System is equipped to handle adjustments for both straight and curved sections. Its design has a radius that can change as the guide’s width is increased or decreased in a curve.

Product Variation Types

Our EZ Guide Rail System is currently available in the following two different configurations:

- Fixed — This variation offers a basic, fixed-width guidance solution and is ideal for single-width products and/or safety concerns like overhead conveyor installations.

- Manual Adjustment — As the entry-level system, this variation is adjusted by manually unlocking its guides and positioning the guide rail by hand. This setup is quite similar to almost all other guide rail systems on the market.

- Incline & Decline Conveyors

Each of these configurations can be made for almost any type of conveyor and still provide the ability to guide through curves. Two of these types — the Fixed and Manual Adjustment — were first introduced at Pack EXPO Connects.

Get Innovative Conveyor Guide Rail Solutions from Span Tech

As a company that thrives on innovation and testing, Span Tech recognizes the importance of utilizing the latest technology in manufacturing. That’s why we’re proud to bring you products like our EZ Guide Rail System. When it comes to providing speciality conveyor solutions like conveyor guide rails, we’re committed to going the extra mile every time. To order our conveyor guide rails for your facility, contact us today!