What Are Spiral Conveyors?

Spiral conveyors pack a long distance into a small footprint. These types of changing elevation conveyors have been used for many decades to cool bakery products as they exit the baking process, as well as other food production applications. The old way of driving these conveyors uses a large, powered drum in the center. The conveyor chain is wrapped around the drum and, through friction between the chain and the drum, the chain is pushed forward. While there is an end drive separate from the drum drive that provides pull tension to the chain, the chain can still slip as the drum rotates.

In a typical drum spiral design, the chain runs against vertical cage bars that are spaced evenly to form a cylindrical shape. These bars have a slip-on plastic cover that protects the system from wear. Unfortunately, the major weakness of all drum-driven spirals is sanitation. Since the conveyor runs on a support system that is fabricated around the drum, the chain must be removed to clean the drum’s cage bars. In fact, some spiral conveyors have thousands of feet of chain, which makes the cleaning process a very long and impractical process. That’s why sanitation engineers typically look in the spirals first during an outbreak of bacteria.

In the case of the technology present in the OutRunner Spiral conveyor, however, this new system changes how these spirals are driven. Let’s look further into this solution and break down the benefits of the OutRunner Spiral machinery.

About the OutRunner Spiral Conveyor System

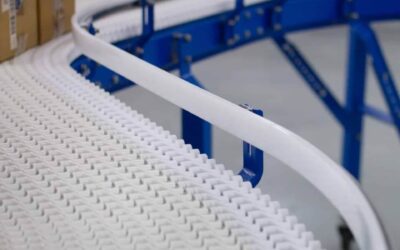

The OutRunner Spiral conveyor system was developed to eliminate the drum drive system altogether. Instead of wrapping the chain around a moving cylinder, this design drives the chain along its outside edge by an external sprocket. OutRunner Spirals use a vertical drive shaft with a sprocket on each tier, and the drum is eliminated in this design. Depending on the diameter and width of the chain, there can be more than one drive shaft with sprockets. These shafts are all tied together on a common mechanical connection with no electronic synchronization used, making this one of the biggest advantages to the OutRunner Spiral.

The second weakness of classical drum drives is getting products off the conveyor chain itself. Drum drive systems use long pitch chains which are usually 2” (50mm). Any product that has an unused 4” in length can have difficulty transferring product off the end of the system. Additionally, transferring smaller items can become even more challenging. One of the benefits of the OutRunner Spiral, though, is that it combats this issue by using a “Pillow Top” chain. This chain has a rounded top which forms a perfect cylindrical shape at the end drive. A knife edge plate is fitted close to the chain, making product transfer successful, even for small items.

What Are Some Other Benefits of the OutRunner Spiral?

One of the biggest advantages to the OutRunner Spiral machine is the very low horsepower required to power the system. Because there are no frictional losses between the chain and a drum, the overall power required to drive the chain is much lower. Also, because there is no massive central drum to turn, the power required to get the system started and stopped is greatly reduced. Here is an example of just what this means:

- The MOAS Spiral in Canada: This project has 1000 feet of 36” chain in 2 spirals, one going up and the other going down. These units use a single unbroken chain so there are no transfers between the units. This system is driven with a single ¼ horsepower drive. All the drive shafts are mechanically connected.

Add the OutRunner Spiral Conveyor System to Your Operations

When it comes to your daily business operations, you may be able to streamline your productivity with help from the OutRunner Spiral conveyor machine. However, Span Tech offers many options to optimize your workflow with dozens of specialty conveyor solutions. Whether you work in beverage production, e-commerce or packaging, our conveyors are highly efficient to handle your production demands for years to come. If you’re ready to reap the benefits of the OutRunner Spiral, or are interested in one of our other specialty conveyor systems, check out our equipment and contact us today with any questions you may have. We look forward to working with you!