Metal vs. Molded Plastic Conveyor Parts

Advancements in the development and production of plastic conveyor parts have resulted in a superior product that dramatically improves conveyor belt performance. In many cases, molded plastic conveyor belt parts are better than metal ones:

- Lower Cost & Better Availability

- Improved Material Characteristics

- Improved Consistency

- Superior Design

Lower Costs

When you can use more affordable products in your equipment, it’s a win-win for all concerned. Because molded plastic conveyor parts are more affordable to produce, everyone gets to keep a little something extra in their pocket, from the manufacturer to the consumer.

Better Availability

Because they’re less costly and easier to produce, it’s feasible to keep larger minimum quantities on hand and easier to get molded plastic conveyor belt parts when you need them.

Designed for Heavy Duty

Because there are very few limitations to designing injection molded parts, modern engineering methods allow them to be designed to optimize strength and thus are surprisingly durable. Molded plastic conveyor parts are designed to handle the most rigorous loading for the application.

More Consistency

Welded metal parts often have issues with warping, which is oftentimes unpredictable and can be hard to control. Molded plastic conveyor belt parts are more uniform than their metal counterparts.

Less QC is Required

Manufactured parts often have to go through several steps during the manufacturing process (such as sawing, milling, turning, welding, coating, etc.). When replacing parts that are coated (like an LPI chain guide), there’s less chance of losing parts due to additional steps in manufacturing, so less quality checking is required.

Improved Material Characteristics

Plastics come in a wide range of material properties. Parts can be made rigid or flexible, high-friction or low-friction. Depending on the design requirements, there’s a plastic material that’s best suited for the application.

Better Design

Molded plastic parts can be engineered with features that are much more ergonomic and safe compared to traditionally manufactured metal parts.

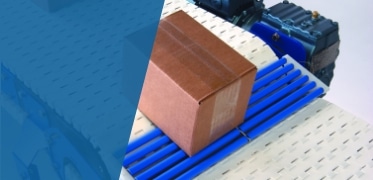

Types of Molded Plastic Parts on a Conveyor Belt

There are dozens of custom-molded plastic wear parts for conveyors replacing metal parts like the hinged steel belt and the sprockets. Today’s conveyor equipment contains plastic parts such as:

- Pulleys

- Plastic Modular Belts

- Rollers

- Bearings/Bushings

- Gears/Sprockets

- Chain Guides & Rails

- Curves/Tracks

- Wear Strips

- Star Wheels

- Augers

- Bumpers

- Hoppers

- Liners

- Bins

Frequently Asked Questions About Custom-Molded Plastic Conveyor Belt Parts

Because they are such a departure from traditional metal and rubber components, people frequently have questions about custom-molded plastic conveyor belt parts.

What Are the Parts of a Conveyor System?

A conveyor system has three main components:

- Belt Guides: This keeps the belt taut and moving smoothly and efficiently.

- Pulleys/Sprockets: Conveyor systems have at least two pulleys – one that operates when the unit is powered up, the other when it’s idling. Pulleys control the conveyor belt’s movement.

- Drive Unit: This enables the system to move efficiently, forward and backward.

What Is a Modular Conveyor System?

A modular belt conveyor contains plastic modules that link together with rods. Sprockets drive the modular belt. Unlike most fabric/plastic belts, modular belts can be made to be pulled through curves and vertical bends. Also, fabric/plastic belts require a tensioning system – modular plastic belts do not. And because they’re more rugged, plastic modular belts are especially useful for moving hot workpieces or items with sharp edges. Chain modules are permeable to air, making modular conveyor equipment the best choice for cooling lines. And due to its simpler design, a modular conveyor system has the added benefit of easy maintenance.

What Is a Plastic Modular Belt?

Modular plastic belting is an alternative to traditional fabric conveyor belt systems. It’s positive-driven, has low tension and eliminates slippage on drives. A plastic modular belt is also durable and simple to maintain, making it ideal for applications in nearly every major industry.

Shop Span Tech Systems for the Best Molded Plastic Conveyor Belt Parts

Span Tech is an industry leader renowned for our durable plastic chain conveyor parts and systems combined with innovations in material handling. Our chains and guides use engineered materials for the best combination of low friction and durability. High-strength plastics are used for items that undergo heavy loading, such as sprockets, chain links, etc. All plastic materials have been selected to be FDA-compliant and are capable of withstanding harsh chemical environments.

We serve a wide range of industries, from food and beverage production to manufacturing, distribution, packaging, pharmaceuticals and cosmetics. We’re committed to building the best conveyor system to meet the needs of our clients. Discover why our molded plastic conveyor belt parts and systems are the right ones for your business. Contact us today so we can get you up and running!