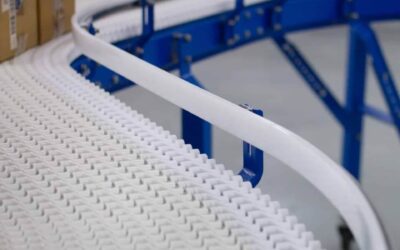

The Bump Rotate is a simple and effective way to change product orientation during the transport cycle, for any operation that requires a specific orientation coming off the line. It uses a roller wheel or tab that can be placed on either side of the conveyor, that when impacted by the product rotate it 90 degrees. If a 180 degree rotation is needed, two Bump Rotates are used in succession. Guide rail spacing can be increased at each rotate point to allow room for the rotation.

BUMP ROTATE FEATURES:

- Intentional obstruction in the path of product on a conveyor which causes the product to rotate and change orientation 90°.

- Mechanical design operates without the use of sensing devices, I/O components, or powered automation.

- Generally requires Guide Rail after the Bump Rotate to straighten the product.

- Temporarily slows the product down on the conveyor which is why a minimum pitch rule must be followed for this application.