COMPONENTS

PLASTIC CONVEYOR CHAIN TYPES

Stop buying complete belt or chain assemblies for small, worn-out sections

When it comes to material handling, one size does not fit all. That’s why Span Tech offers a wide range of innovative conveyor chain options designed to meet the specific needs of various industries, from food and beverage to pharmaceuticals, packaging, and distribution. Our conveyor chains are engineered for durability, flexibility, and efficiency, ensuring optimal performance and long-lasting reliability. Whether you need a chain for tight turns, delicate product handling, or high-speed applications, Span Tech has the perfect solution.

What Makes Span Tech Conveyor Chains Unique?

Wide Range of Chain Options: Span Tech provides an extensive selection of conveyor chain options, each designed for specific applications and environments. From our versatile 50mm SuperTight Chain to our low profile Pillow Top Chain and the king of accumulation Tube Top Chain, we offer solutions that cater to various product types, handling requirements, and operational challenges.

Modular and Customizable Designs: Our conveyor chains are built with a modular design that allows for easy customization to suit any production line layout. This flexibility means you can tailor your conveyor system to handle different product types, sizes, and weights without compromising on efficiency or reliability. The modular design also allows for easy replacement of small sections instead of replacing an entire belt.

Durability and Low Maintenance: Span Tech conveyor chains are constructed from high-quality materials, ensuring long-term durability and minimal maintenance requirements. This robust construction reduces downtime and maintenance costs, providing a cost-effective solution for your material handling needs.

Smooth and Quiet Operation: Designed for smooth, low-noise operation, our conveyor chains reduce friction and wear, enhancing product flow and creating a quieter working environment. This is particularly important in industries where noise reduction and gentle handling are essential, such as food processing and pharmaceuticals.

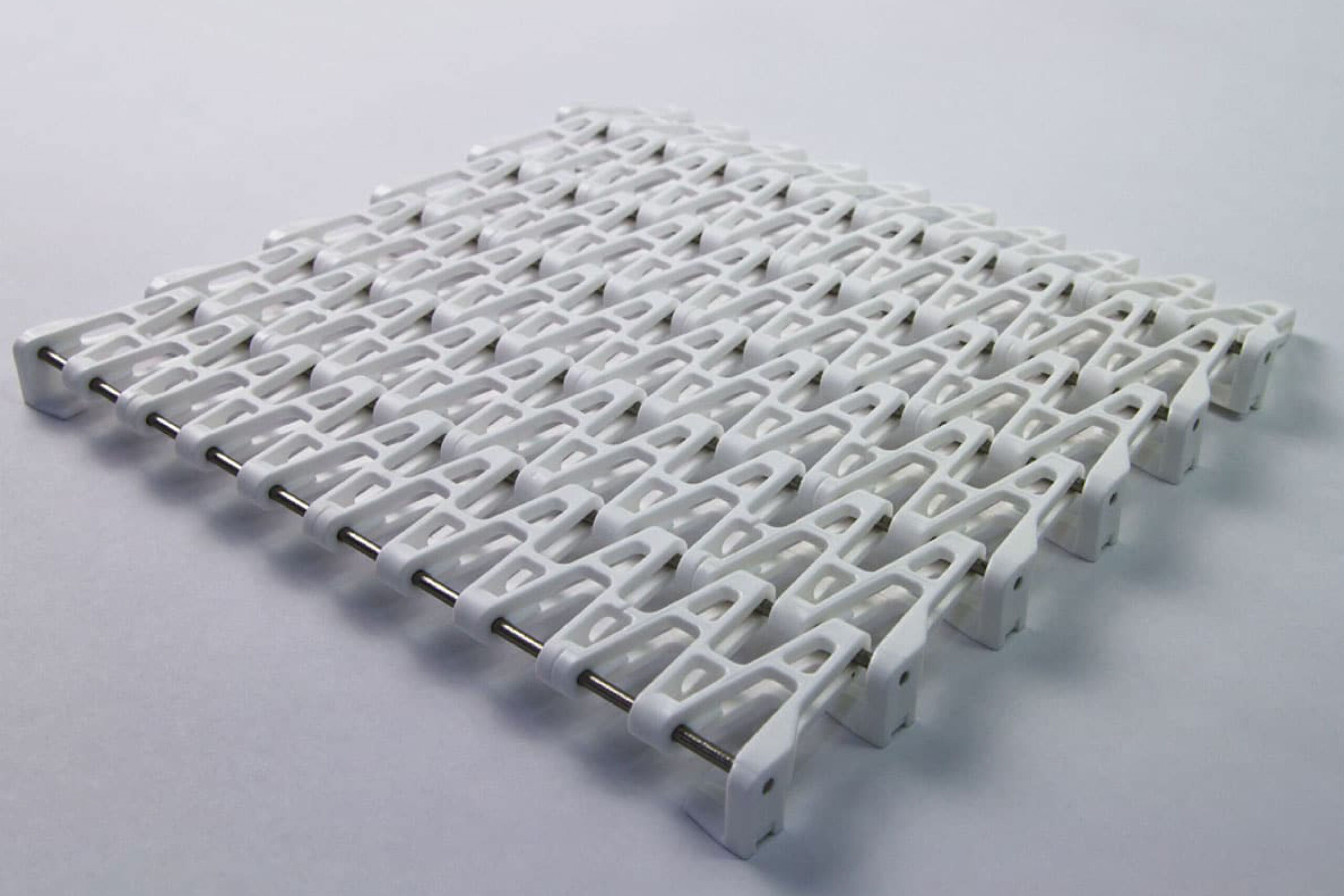

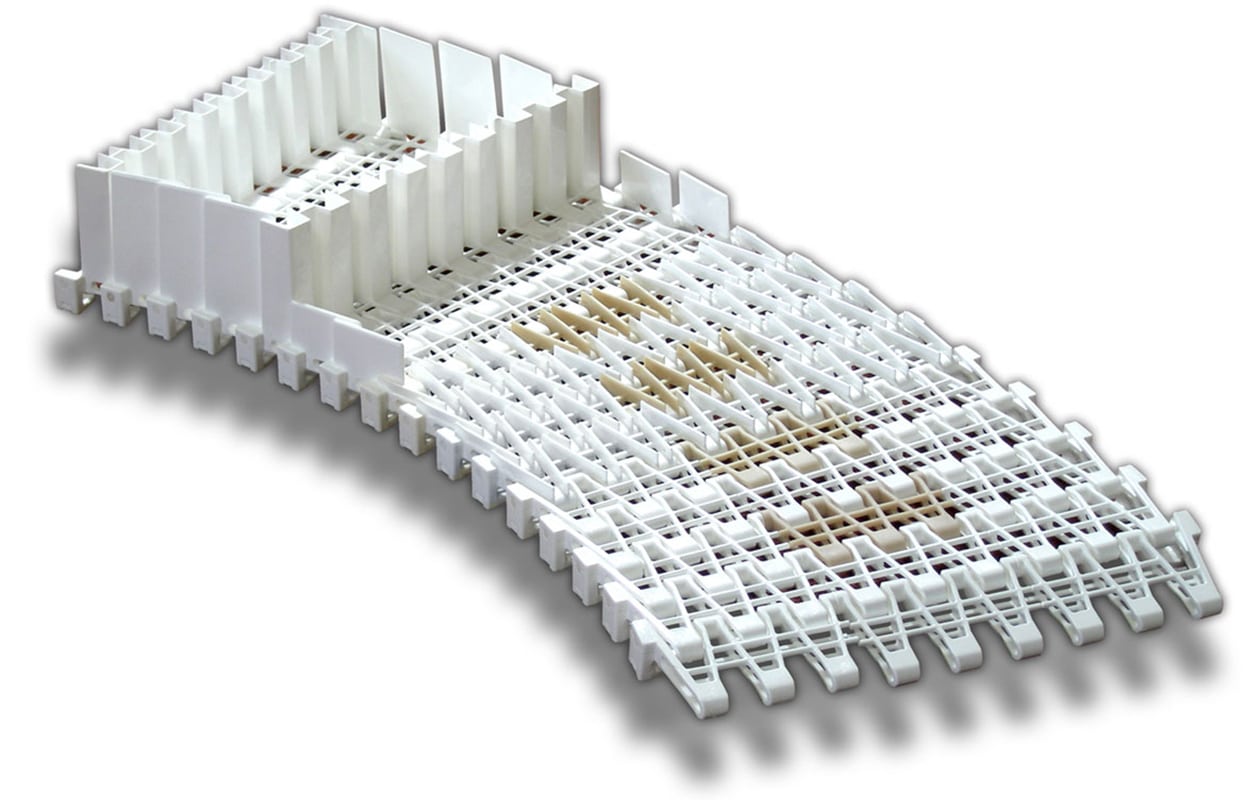

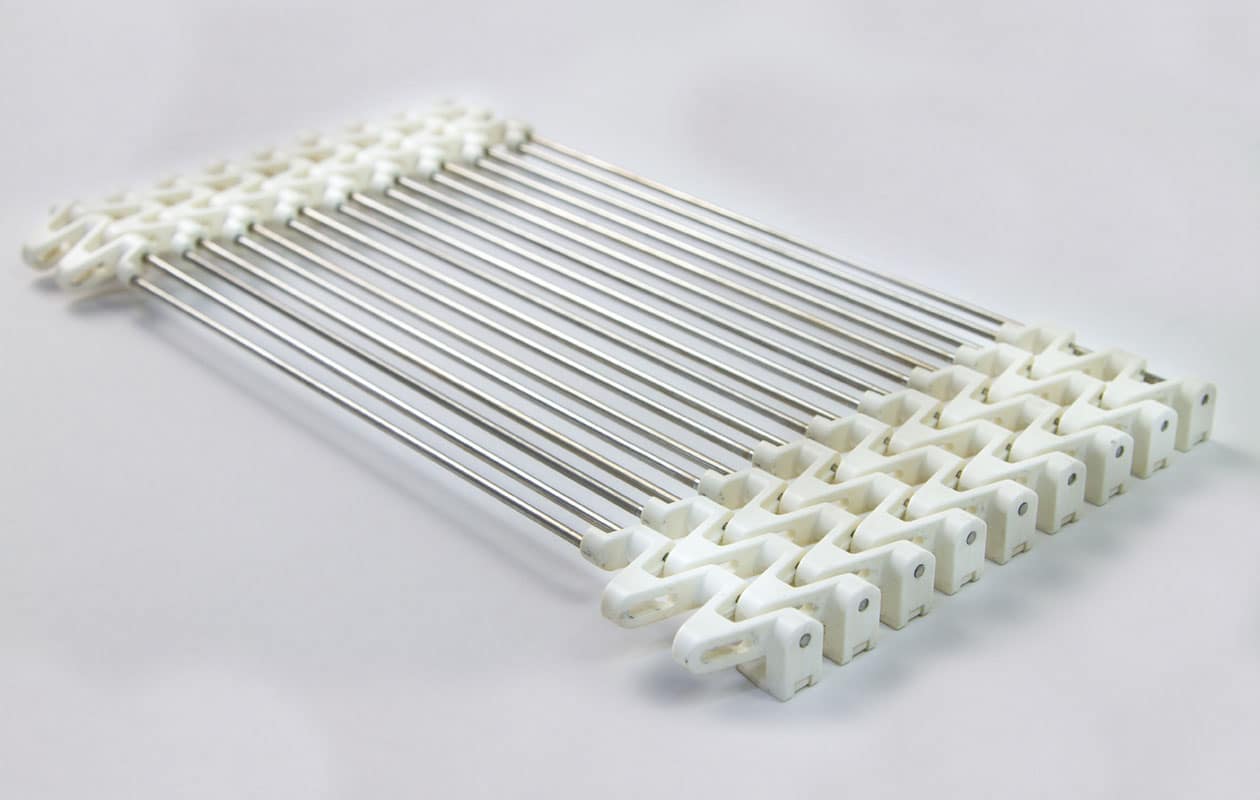

Tube Top Roller Conveyor Chain

Tube Top Roller Conveyor Chain is engineered to optimize your accumulation needs and enhance your production line’s efficiency while protecting the integrity of your products.

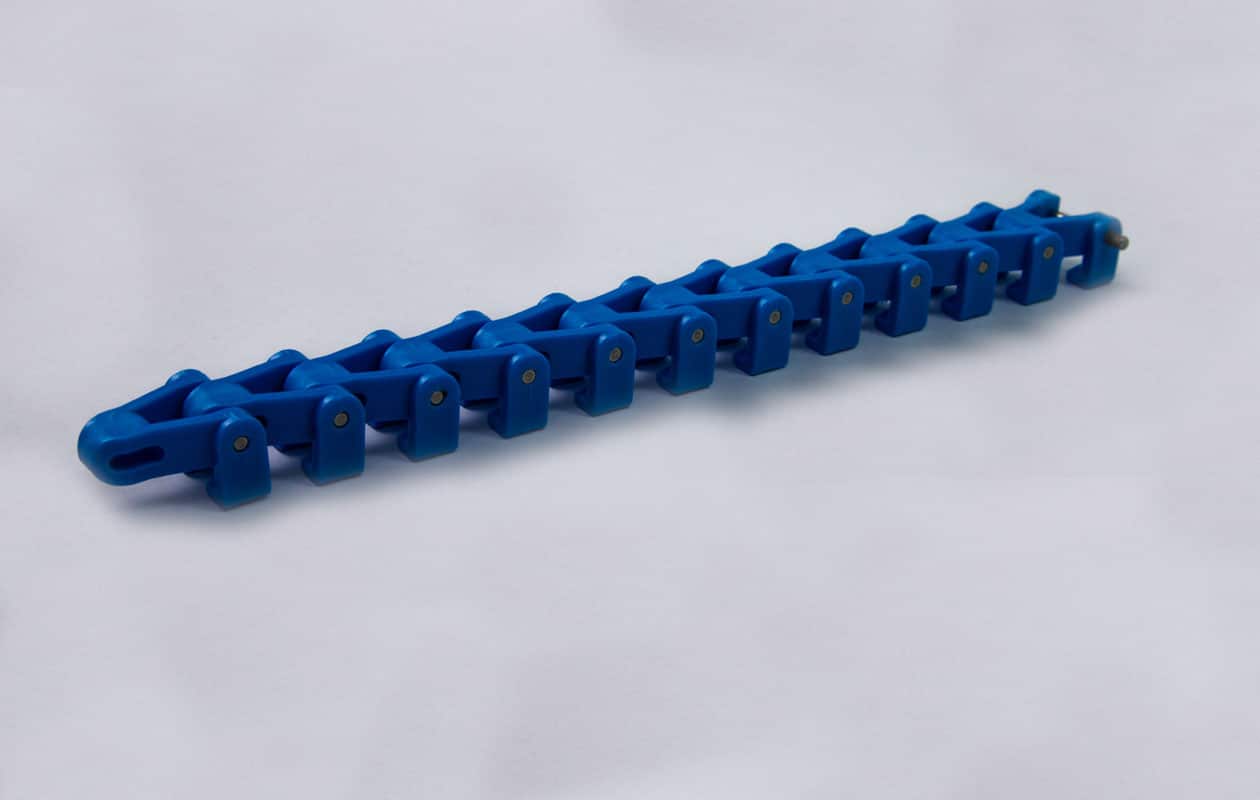

50mm Supertight Conveyor Chain

The longer pitch of 50mm SuperTight chain means it uses half the number of links than that of 25mm Supertight to get the same job done. This chain is capable of extremely tight turning radiuses. With a more open design it allows more airflow to the product.

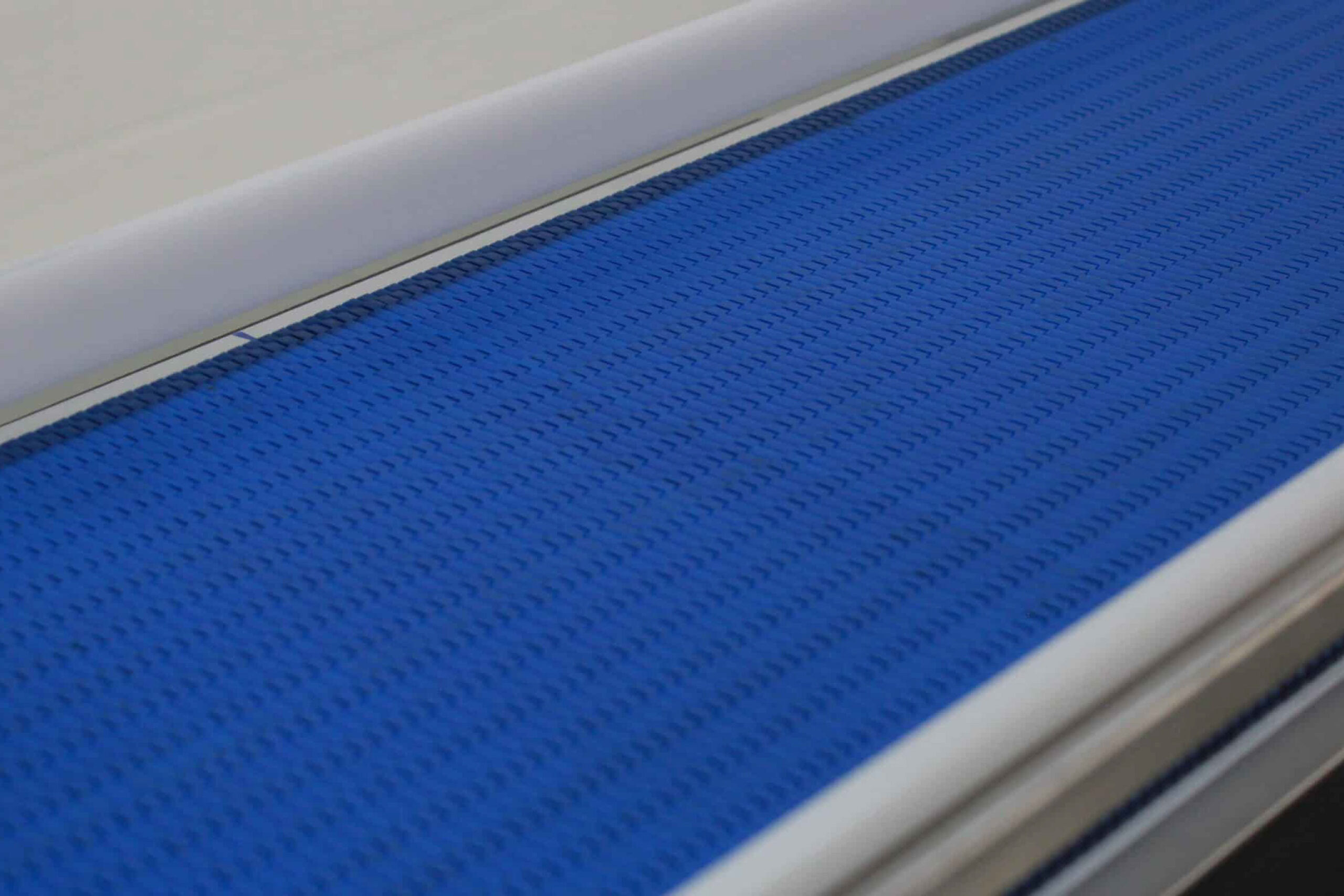

50mm Pillow Top Conveyor Chain

Pillow Top chain has a curved top profile making it perfect for transferring very small and thin products that could otherwise get caught or snagged in more traditional transfers.

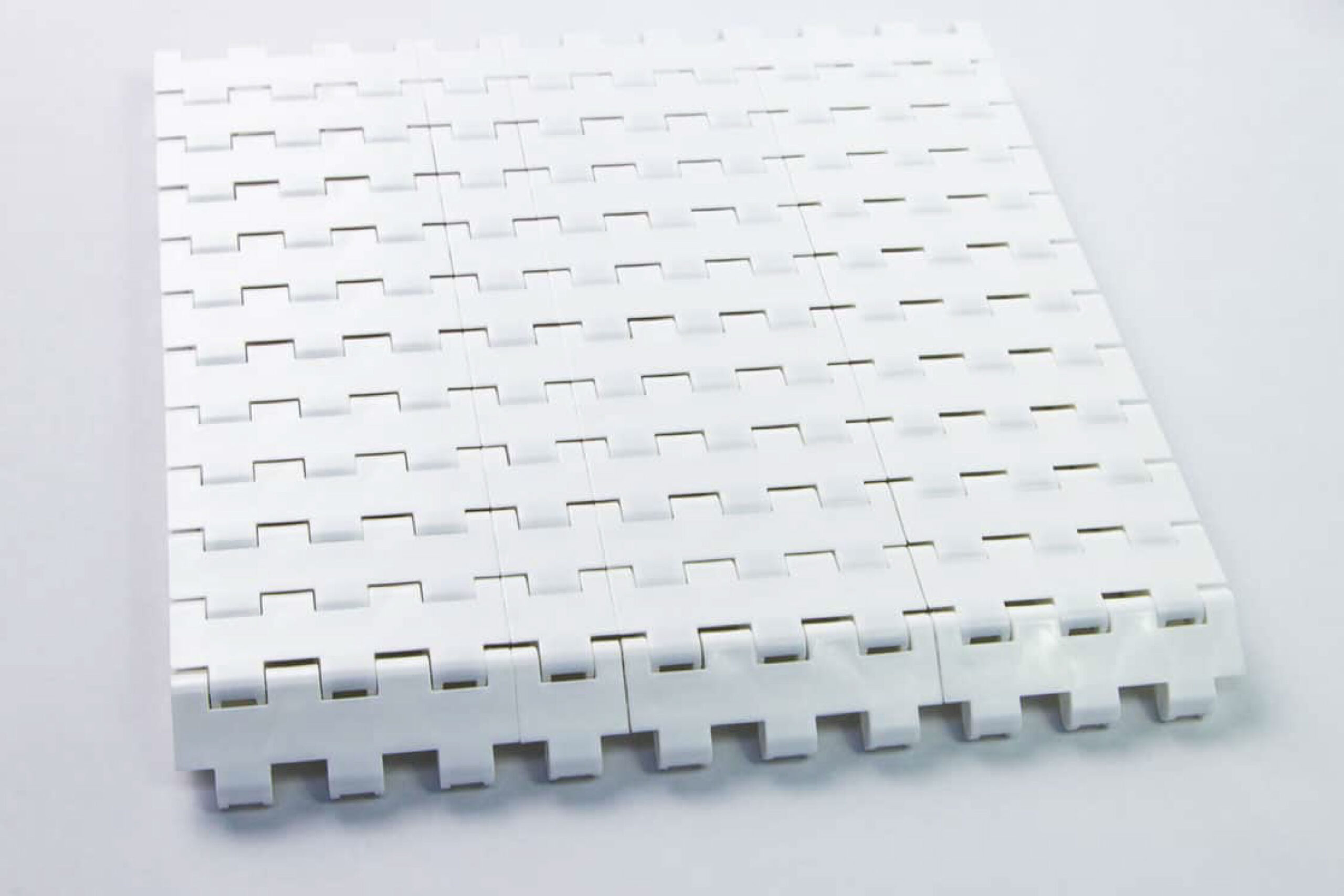

Closed Top Conveyor Chain

Sometimes you need a conveyor chain with a smooth, closed carrying surface, that’s when Closed Top chain comes to the rescue.

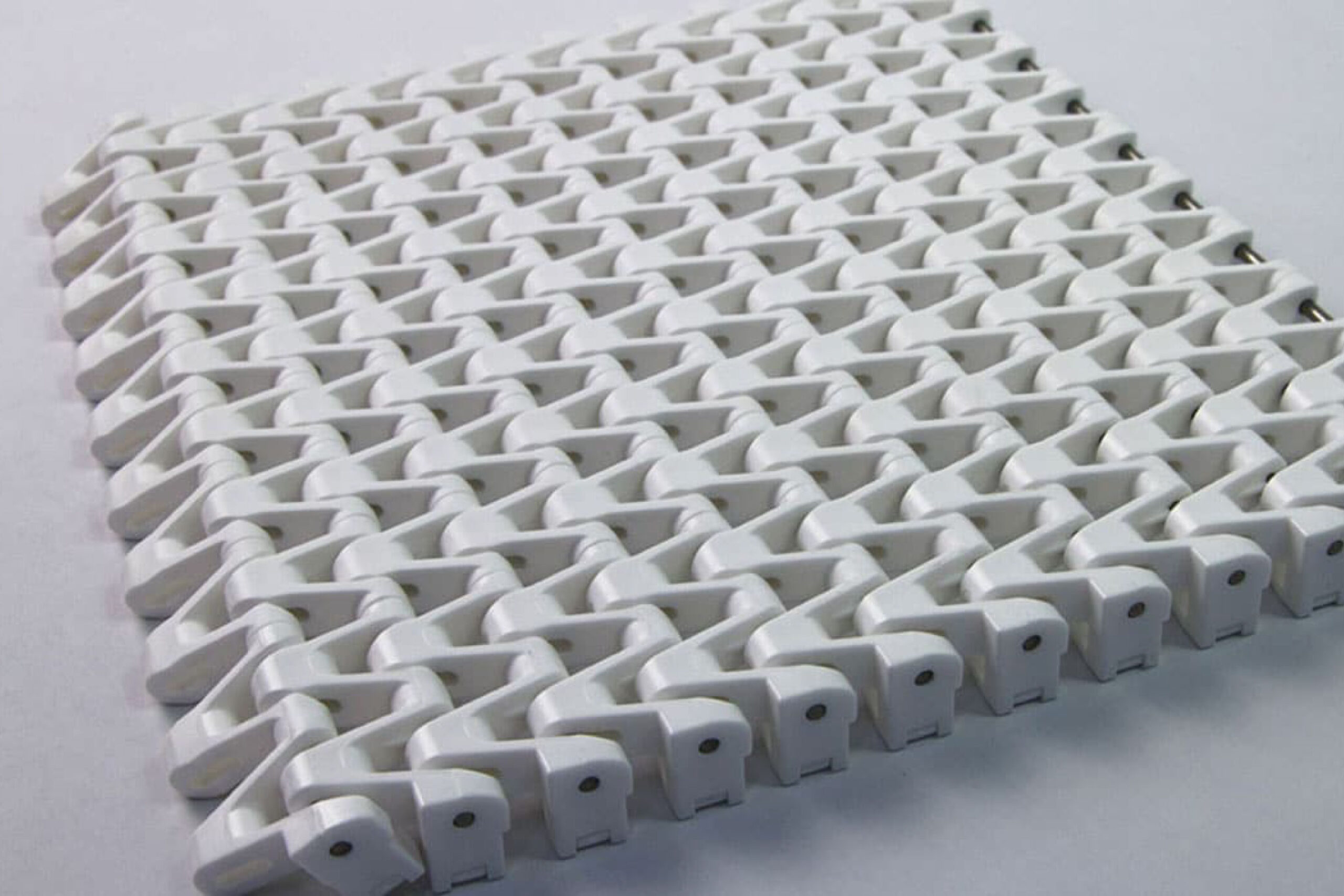

25mm Supertight Conveyor Chain

Supertight is a lighter version of MultiSpan and offers and extremely tight turning radius. Out of all of our chain families 25mm Supertight gives you the most chain link options to choose from giving you ultimate control of your products.

MicroSpan Conveyor Chain

Modular chain designed to replace belt conveyor systems. End-to-end product movement has never been more adaptable than with MicroSpan conveyor chain and conveyor transfers.

MaxiSpan Conveyor Chain

Maxispan chain has many of the same features as 50mm Supertight chain with the main difference being the use of plastic chain rods making it a perfect options for metal detectors.

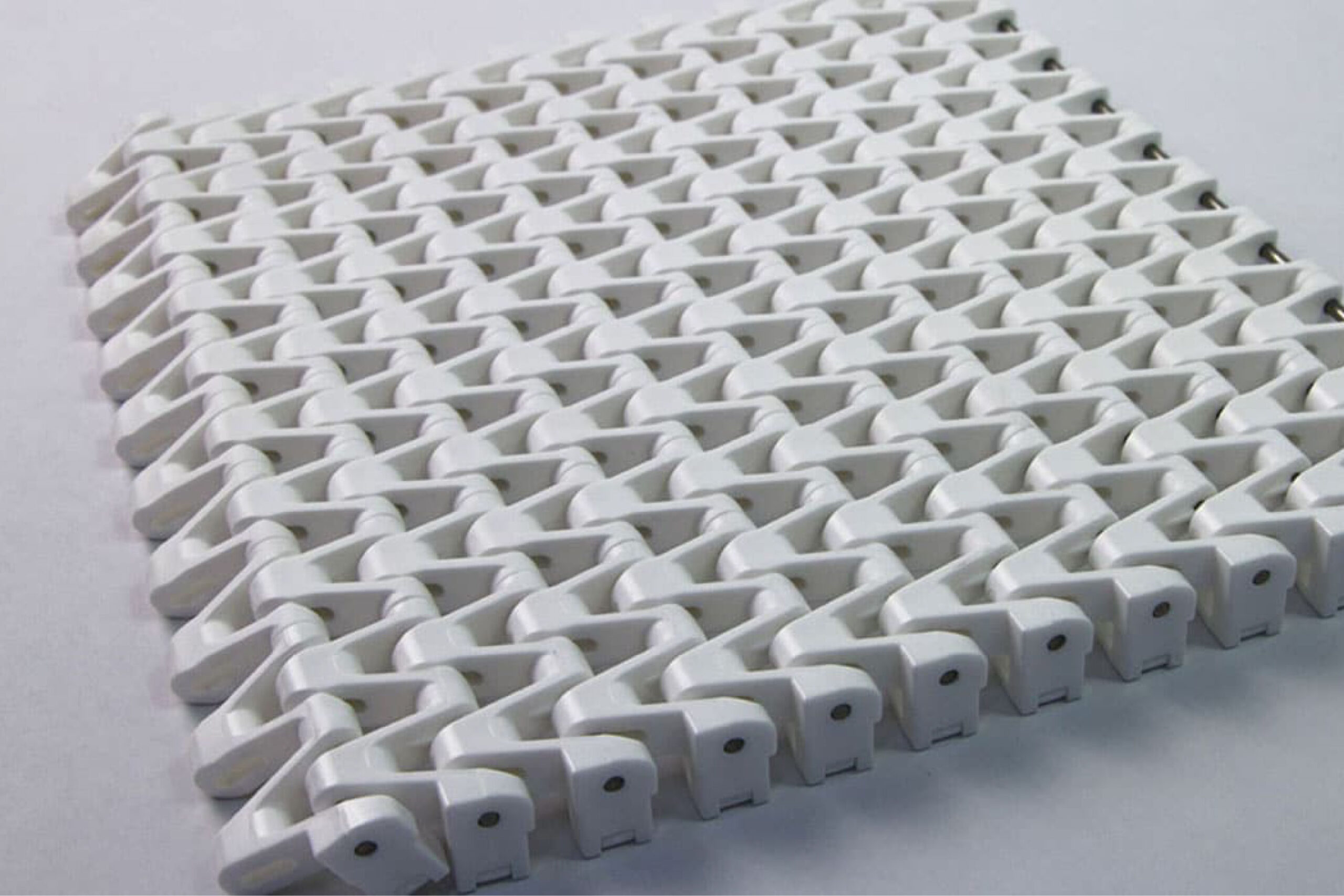

MultiSpan conveyor chain

Your strong, versatile solution with a compact design, MultiSpan chains all polypropelene construction allows for use in a more corrosive environment. Its large amount of different chain types make it adaptable to any conveying challenge.

MonoSpan Conveyor Chain

Maxispan chain has many of the same features as 25mm Supertight chain with the main difference being the use of plastic chain rods making it a perfect options for metal detectors.

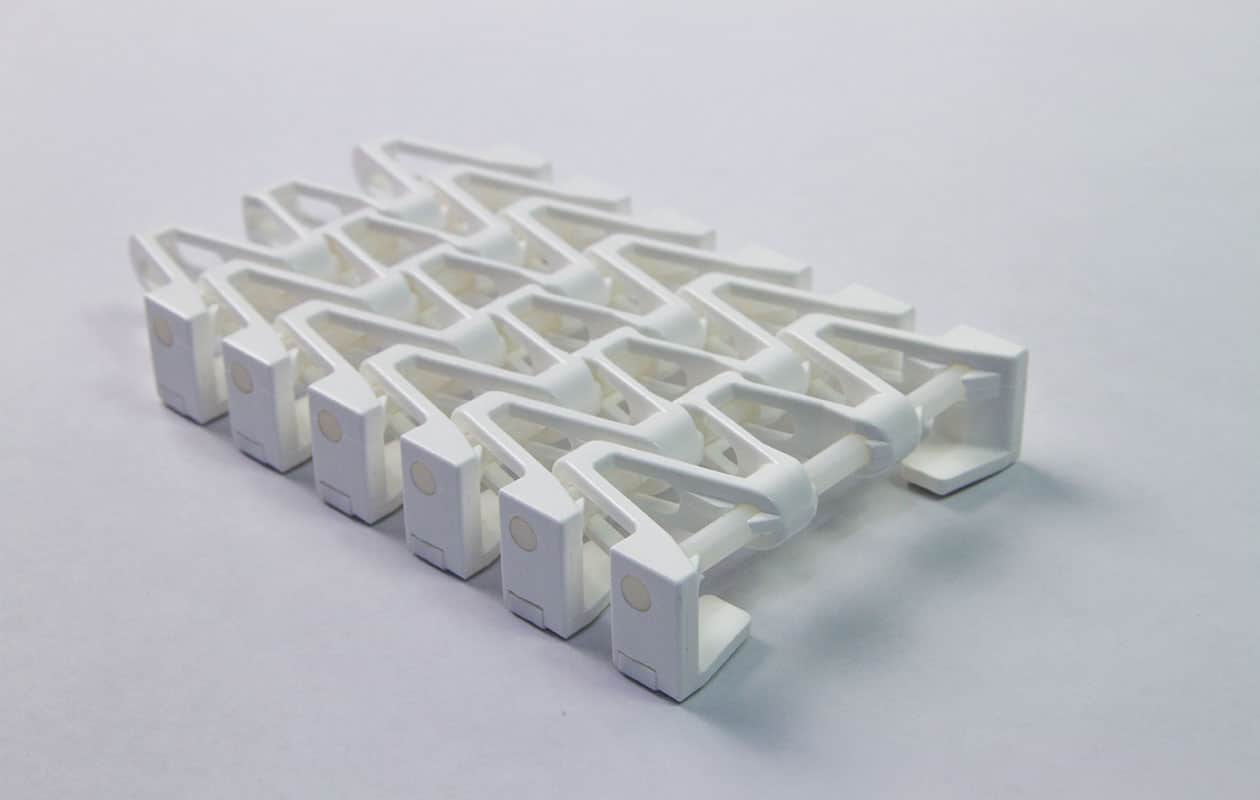

MiniLink Conveyor Chain

MiniLink is the ideal choice for extremely small individual lanes of product. It is perfect for creating seperation of products ever so slightly.

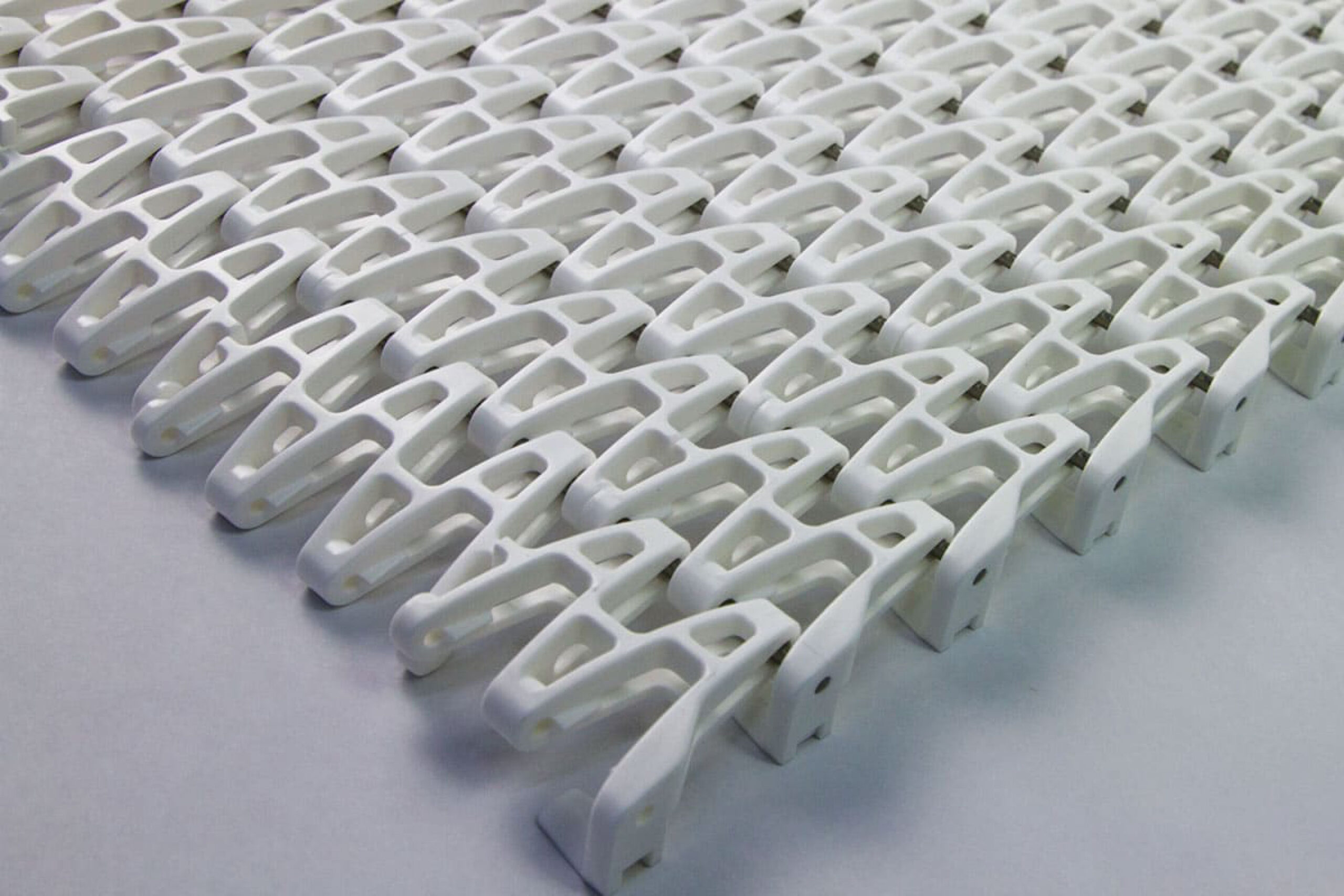

J Trax Conveyor Chain

J Trax conveyor chain option has an extremely open design concept which allows a large amount of airflow to the product. This makes it an ideal solution for the baking industry or any application where airflow is a must.

Downloads

Applications

Industries

FAQs About Plastic Conveyor Chains

What are the Advantages of using plastic chain VS metal chains?

Plastic conveyor chains are lighter, quieter, and more resistant to corrosion compared to metal chains. They are also less abrasive, which helps protect both the conveyed products and the conveyor system itself. Additionally, plastic chains require less lubrication, reducing maintenance needs and operational costs.

Can plastic chains handle heavy loads?

Yes, plastic conveyor chains are engineered to handle a wide range of loads, including heavy products. While metal chains are typically stronger, modern plastic chains are designed with high-strength materials that can support substantial weights, making them suitable for many industrial applications.

How easy is it to replace or repair plastic chain?

Plastic conveyor chains are designed for easy maintenance. They are typically modular, allowing for quick replacement of damaged sections without the need to replace the entire chain. This modularity reduces downtime and maintenance costs.

How do I choose the right plastic conveyor chain for my application?

When selecting a plastic conveyor chain, consider factors such as load capacity, environmental conditions (e.g., temperature, humidity, chemical exposure), speed requirements, and the type of products being conveyed. Consulting with a conveyor specialist can help ensure you choose the right chain for your specific needs.