CONVEYOR ADD ONS

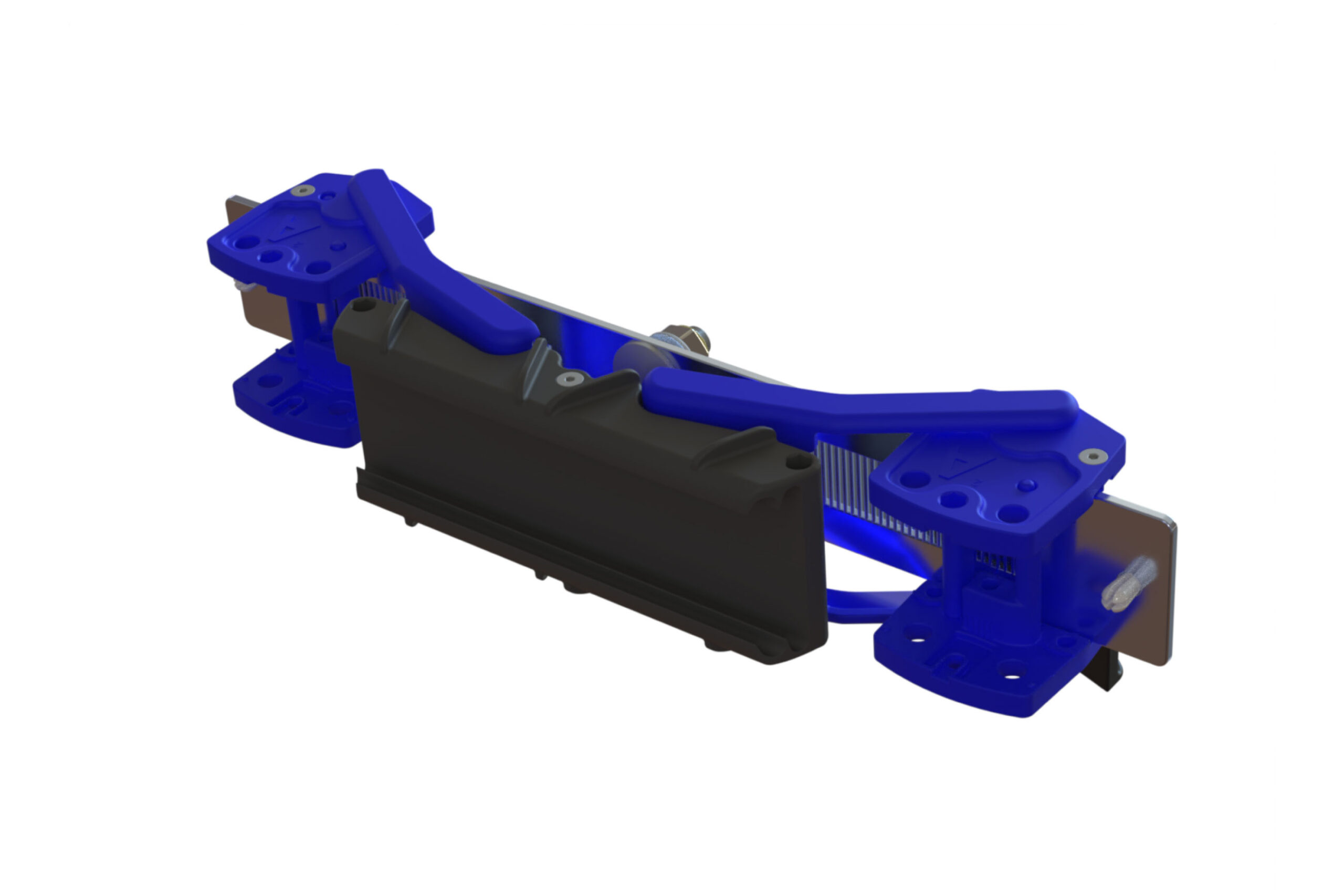

EZGUIDE™ CONVEYOR GUIDERAILS

Ultimate Flexibility and Precision for Product Handling & Guidance

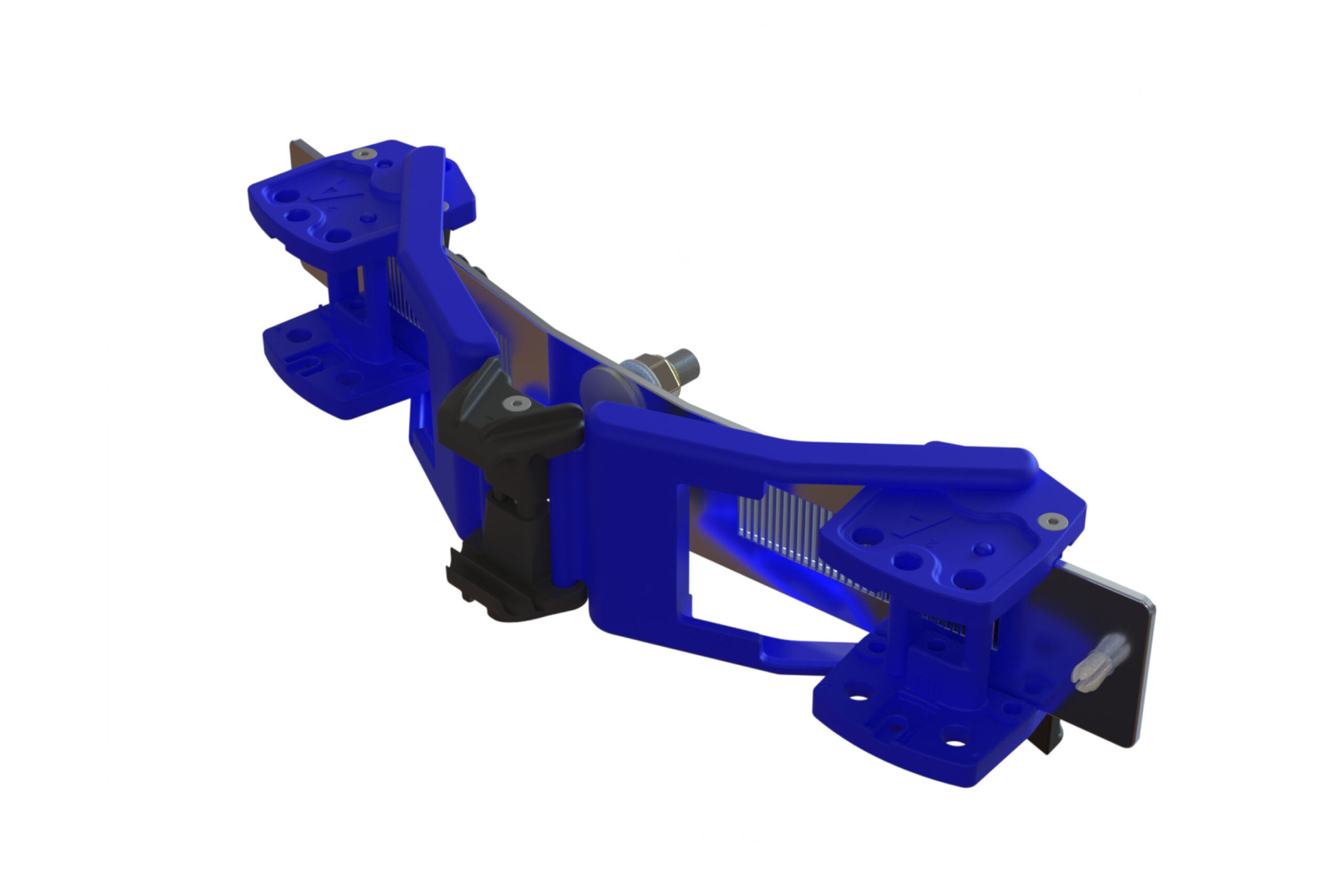

When it comes to maintaining efficiency and precision in production lines, proper product guidance is essential. The Span Tech EZGUIDE Conveyor Guide Rails Add-On offers a highly flexible, durable, and easy-to-use solution for managing product flow on your conveyor system. Designed to adjust quickly without the need for tools, the EZGUIDE system is perfect for operations requiring frequent changeovers or handling diverse product types and sizes.

Enhanced Safety Features:

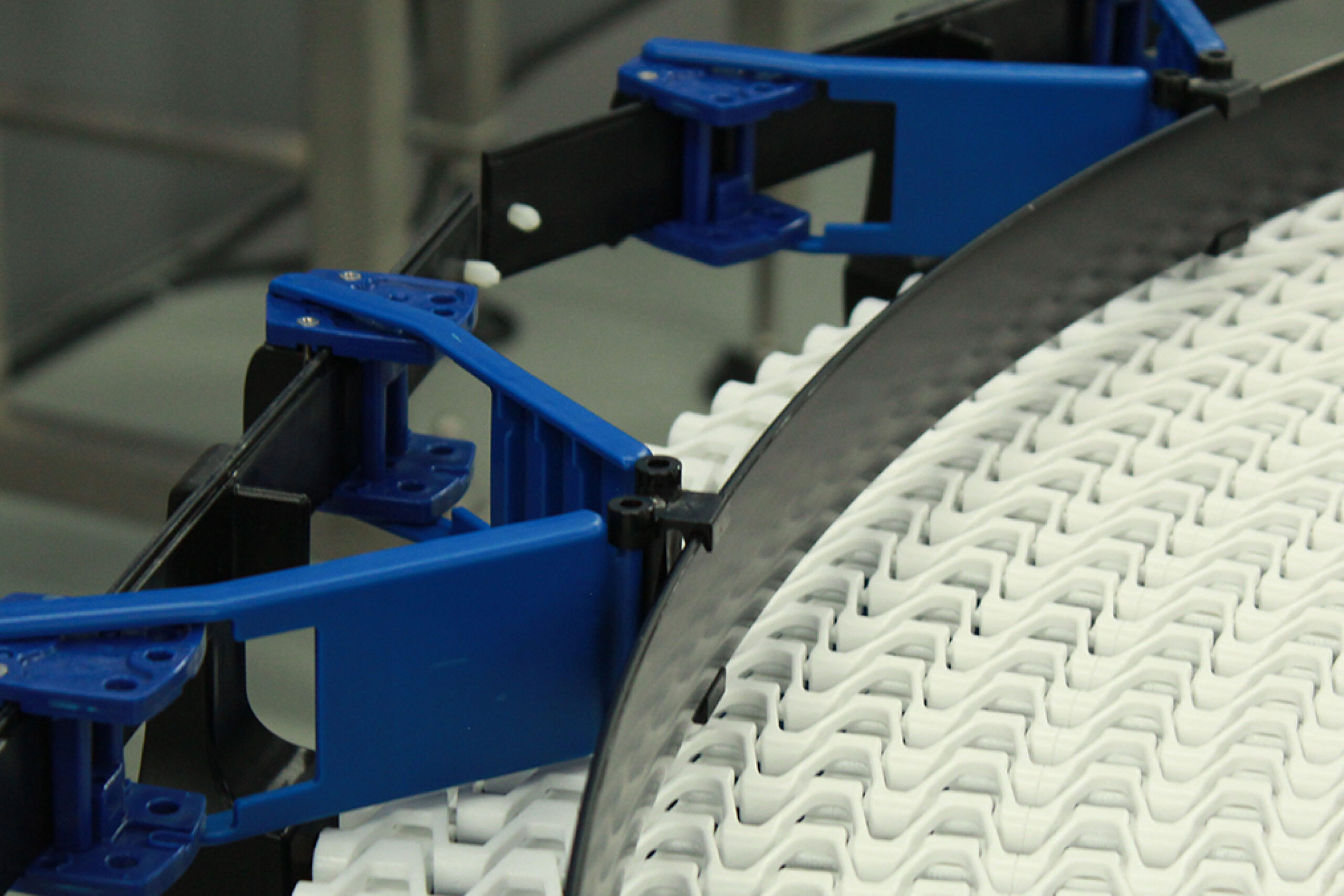

The most notable feature of the EZGUIDE™ conveyor guide rail system is it does not have any protruding brackets or rods which could be a major safety hazard. Traditional conveyor guide rails use a solid-mounted rod to mount their guide rail. When the rail is adjusted to its “retracted” position, these rods stick out from the sides of the conveyor, becoming a place where someone can easily get their clothes or other body parts caught. The EZGUIDE™ system does not have any mechanical components which protrude from the sides of the conveyor during adjustment. All the mechanics are done without the need to protrude past the conveyor, keeping everything safe for those walking close to the conveyors.

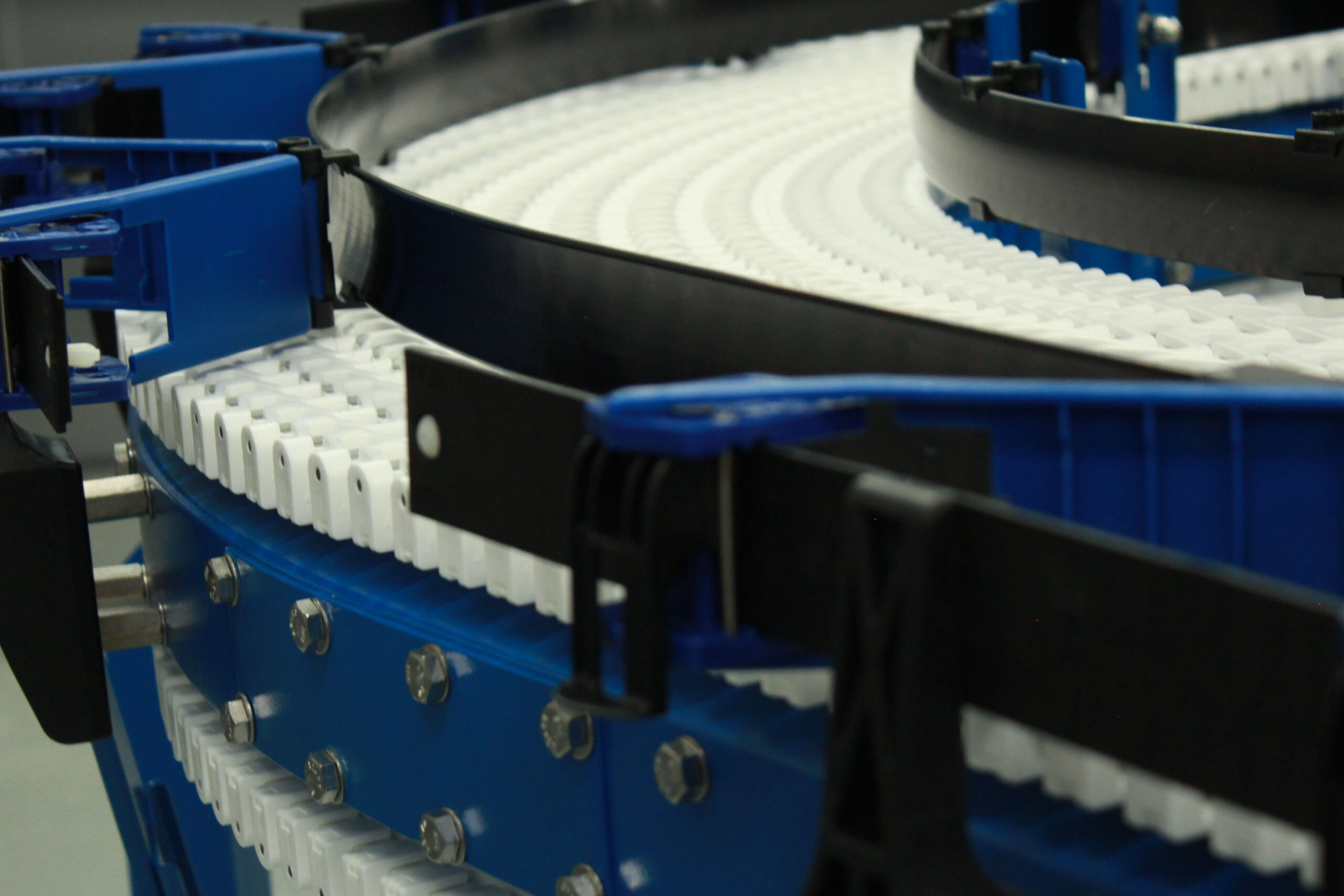

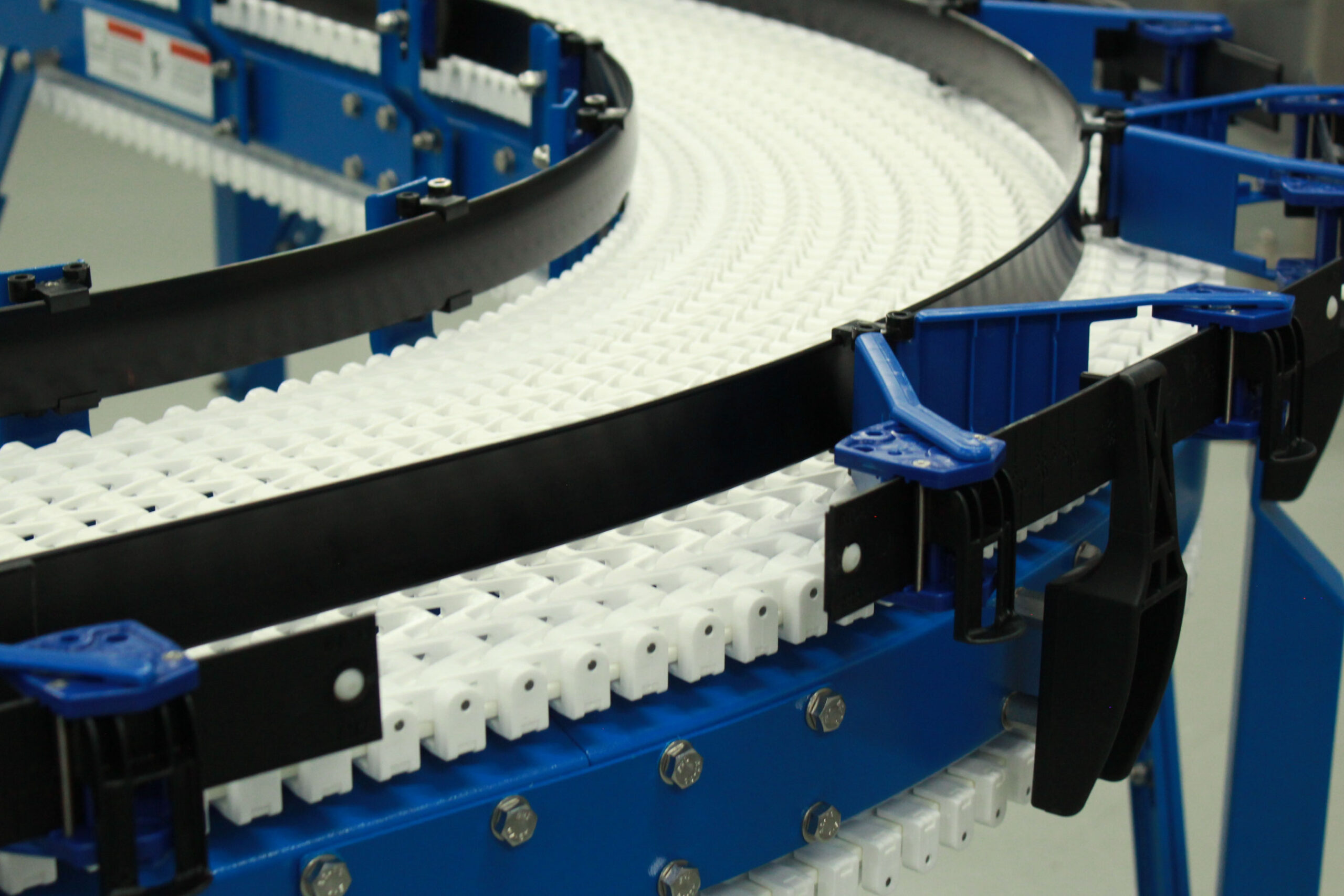

Conveyor Guide Rails Adjustable Through Curves:

Another feature of the EZGUIDE™ conveyor guide rails is it is designed to remain adjustable through curves. That is, the radius of the guides can change as the guide width is increased/decreased in the curve. While there are many traditional guide rail systems which can be made to adjust their width in straight sections, there are very few that can truly be adjustable through a curved portion of conveyor. The reason is because changing the radius of a section is difficult – the guides must bend, and the length of the guide has to increase/decrease as the radius is changed. EZGUIDE™ conveyor guide rails handle both of those problems with its unique design.

EZGUIDE™ Conveyor Guide Rails Available in 2 options:

- Fixed- This option provides a basic fixed-width guidance solution for single-width products and/or safety concerns (such as overhead conveyor installations).

- Manual Adjustment- This is the entry-level system which is adjusted by manually unlocking the guides and positioning the guide rails by hand. This is very similar to almost all other guide rail systems on the market.

Tool Free Adjustablility

Easily adjust EZGUIDE rails with a simple lock tab, perfect for facilities with diverse products or frequent changeovers.

Enhanced Safety

Non-protruding rods and tool-free design reduce injury risks, creating a safer and more satisfying work environment.

Versatile Applications

Adapts to various product sizes and conveyor types, suitable for industries like food, pharma, and packaging.

COMMONLY USED IN THESE INDUSTRIES

Reliable, Easy-to-Adjust EZGUIDE Guide Rails for Any Conveyor

Span Tech’s EZGUIDE Guiderail System is a cutting-edge solution designed to keep products aligned, stable, and moving smoothly along a conveyor system. Unlike traditional guiderail systems that require constant manual adjustments, the EZGUIDE system provides an effortless, tool-free way to adjust for different product sizes and shapes. This makes it ideal for industries like food and beverage, pharmaceuticals, e-commerce, and packaging, where product handling precision is essential.

Applications For EZGUIDE Conveyor Guide Rail

Food and Beverage Industry

- Keeping bottles, cans, and cartons properly aligned during high-speed processing.

- Preventing food products from shifting or colliding during transport.

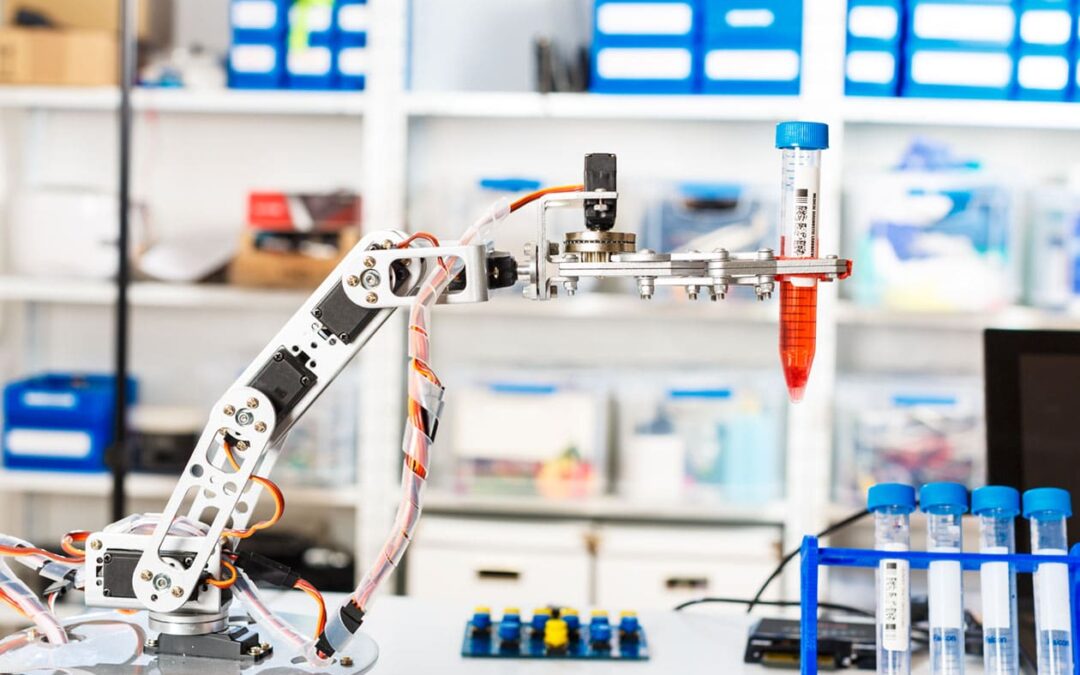

Pharmaceutical Industry

- Ensuring precise positioning of blister packs, vials, or small medical devices.

- Maintaining product integrity during labeling and packaging.

E-Commerce and Distribution

- Stabilizing packages and parcels for efficient sorting and scanning.

- Reducing misalignment in high-speed fulfillment centers.

Packaging and Manufacturing

- Guiding boxes, trays, or components through automated assembly lines.

- Preventing product jams and ensuring smooth transitions between conveyor sections.

Rules of thumb

Features & Benefits

Tool Free Adjustability

Easily adjust EZGUIDE rails with a simple lock tab, perfect for facilities with diverse products or frequent changeovers.

Enhanced Safety

Non-protruding rods and tool-free design reduce injury risks, creating a safer and more satisfying work environment.

Versatile Applications

Adapts to various product sizes and conveyor types, suitable for industries like food, pharma, and packaging.

Cost Effective Solution

Durable, low-maintenance design offers a great return on investment, enhancing efficiency without extra costs.

Improved Product Handling

Provides stable, precise guidance for consistent product positioning, reducing damage and ensuring quality.

Videos

Gallery

Downloads

customizable

Span Tech offers tailored solutions to meet specific operational needs, whether for delicate handling or heavy-duty operations.

Durabile & Efficient

Span Tech conveyors are engineered for durability, built with high-quality materials to withstand tough environments and reduce maintenance costs. Their robust design ensures long-lasting, reliable performance, maximizing uptime and productivity for any operation.

Partnership

OEMs, Distributors, Integrators and End Users, choose Span Tech for innovative and reliable conveyor solutions tailored to unique needs. Our systems offer seamless integration, durability, and reduced maintenance, maximizing ROI and efficiency.

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

SpanTech’s EZGuide rail system has greatly improved change over times on our bottle filling line. We fill a wide range of bottle sizes and styles. The EZGuide system makes it easier and quicker to adjust between larger and smaller containers. One great feature is the lack of protruding rods from the sides of the conveyors. We are looking at installing this rail system on more filling lines in the near future.

I feel like Span Tech offered us more diversity, custom conveyors, especially for the products that we run and how we run them.

The sales and service personnel at Span Tech are always very professional and helpful throughout the entire process, from design phase, quoting, order processing and delivery of equipment. Quality equipment, professional service and knowledgeable personnel are why Arr-Tech’s choice for conveyor systems will always be Span Tech.

Paradise Tomato Kitchen has used Span Tech conveyors for our sanitary food pouch conveying systems for many years. These sanitary conveyors have provided the best cost of ownership, or the lowest net present value, of any processing conveyors we have used in our food manufacturing plants. These conveyors are easy to widen, lengthen or design for curves and angles to convey our flexible pouches between unit operations.

The quality of this product speaks for itself. Where the difference lies is in the quality of the organization. The whole Span Tech organization – Sales, Engineering, Service – works to serve customers’ needs, not just sell conveyors.