CONVEYOR ADD ONS

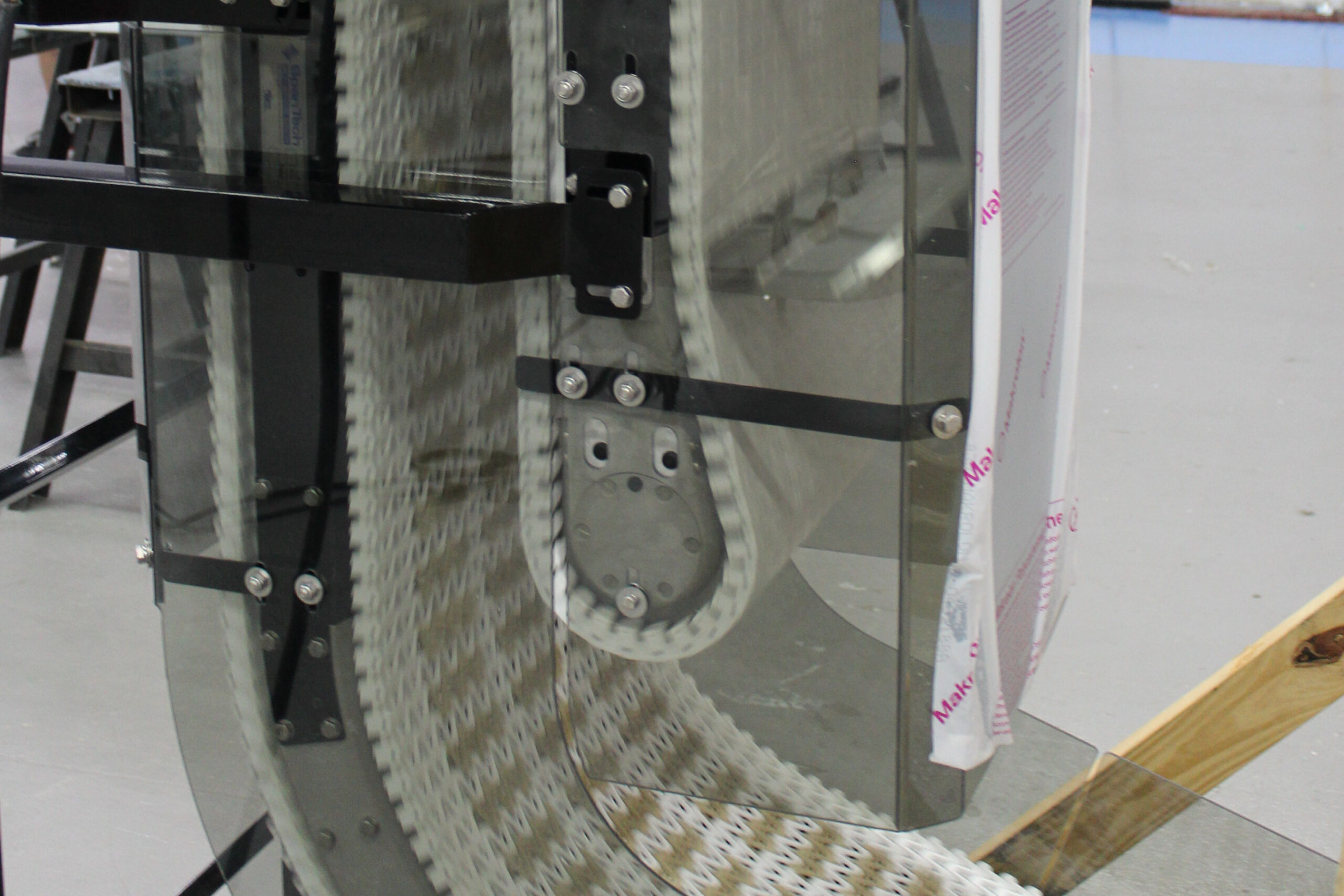

LEXAN CONVEYOR GUARDING

Superior Protection and Visibility for Your Conveyor System

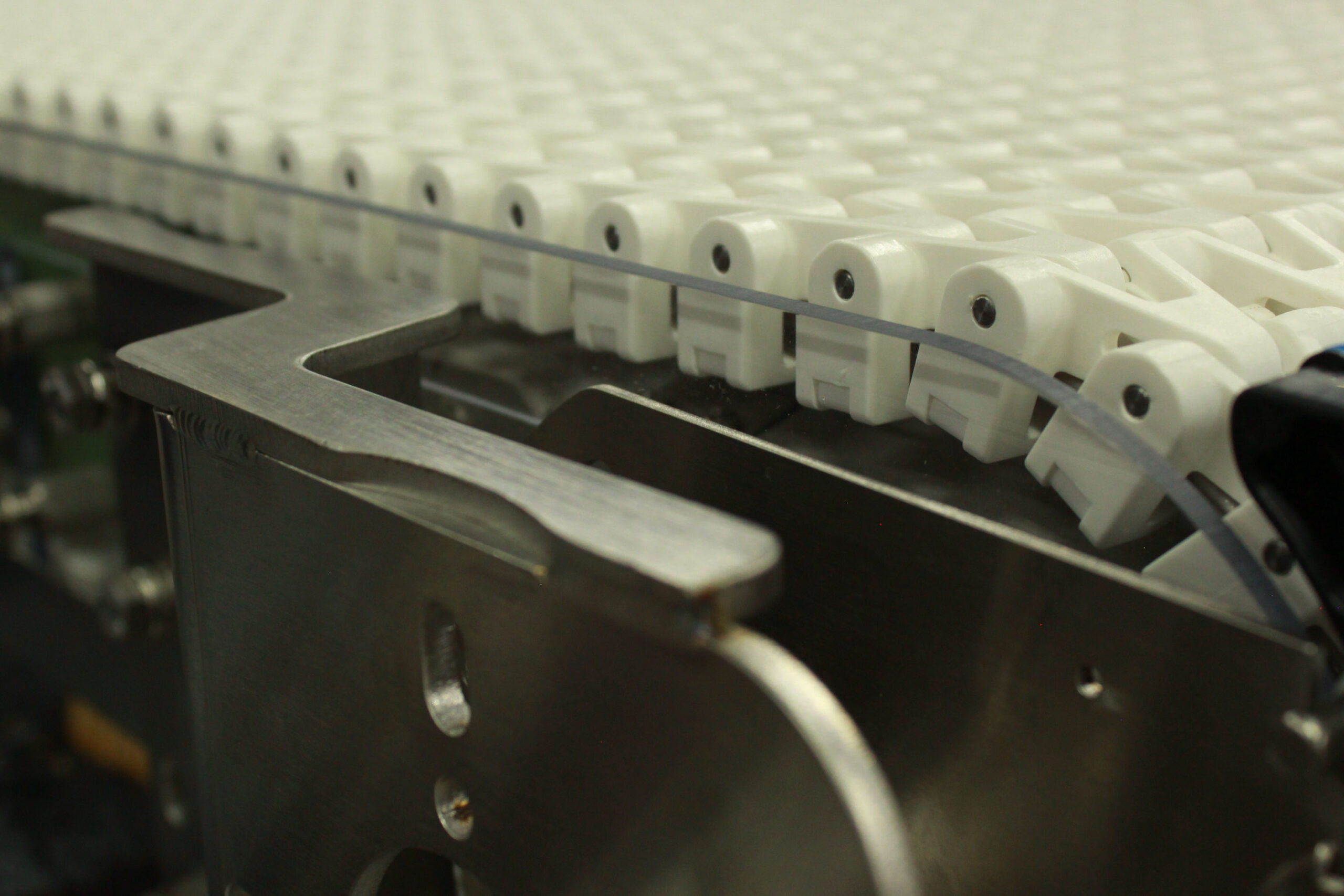

Ensuring the safety of personnel while maintaining high levels of productivity is a top priority in any manufacturing or production environment. The Span Tech Lexan Safety Guarding Add-On provides an optimal solution for protecting employees from moving parts while still allowing clear visibility of the conveyor system. Made from high-quality Lexan polycarbonate material, this safety guarding add-on is designed to deliver durability, visibility, and safety in one comprehensive package.

Lexan guarding is an option for certain applications where safety could be a concern. Lexan guarding covers the conveyor where parts are moving at very high speeds to ensure the safety of the members who station it. It ultimately blocks unintentional direct contact with the conveyor resulting in minimal opportunity for injury.

Improved Safety

Lexan Safety Guarding creates a protective barrier, reducing workplace accidents, lowering injury costs, and boosting employee morale.

Durable Construction

Made from tough Lexan polycarbonate, the guard resists impacts, scratches, and wear, ensuring long-lasting protection in industrial environments.

COMMONLY USED IN THESE INDUSTRIES

Keep Your Production Line Secure with Lexan Guarding Add-Ons

Span Tech’s Lexan Safety Guarding is a durable and transparent protective barrier designed to enhance workplace safety and cleanliness by shielding workers from conveyor components and products in motion. This safety feature is ideal for industries such as food processing, beverage manufacturing, pharmaceuticals, and packaging, where maintaining visibility, hygiene, and safety is crucial.

Applications For Lexan Conveyor Guarding Add Ons

Food Industry

- Protecting workers from moving conveyor parts while ensuring a hygienic barrier between food products and external contaminants.

- Commonly used in packaging, sorting, or processing areas.

Beverage Industry

- Shielding high-speed conveyor lines for bottles, cans, or cartons to enhance worker safety.

- Preventing spills or debris from escaping the conveyor line.

Pharmaceutical Industry

- Maintaining cleanroom standards by preventing contamination from conveyor components.

- Providing a clear and protective barrier for delicate products like medications or medical devices.

Packaging and E-Commerce

- Protecting workers in high-speed packaging or assembly lines.

- Preventing accidental damage to fragile or sensitive items.

Features & Benefits

Improved Safety

Lexan Safety Guarding creates a protective barrier, reducing workplace accidents, lowering injury costs, and boosting employee morale.

High Visibility

Clear Lexan material lets operators monitor conveyor systems without removing the guard, minimizing downtime and increasing efficiency.

Durable Construction

Made from tough Lexan polycarbonate, the guard resists impacts, scratches, and wear, ensuring long-lasting protection in industrial environments.

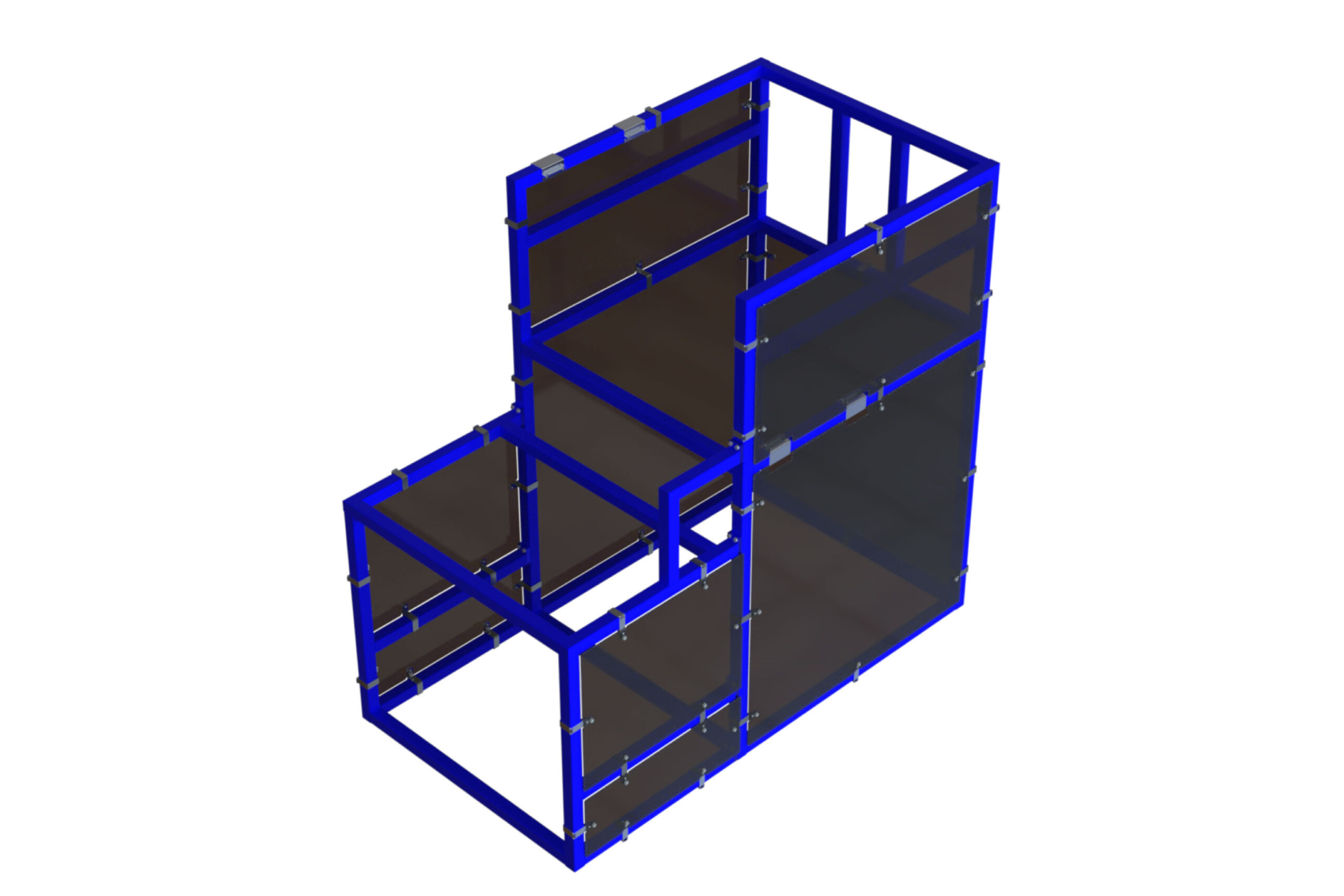

Quick Access Panels

Easily opened panels provide safe, convenient access for maintenance, adjustments, or inspections.

customizable

Span Tech offers tailored solutions to meet specific operational needs, whether for delicate handling or heavy-duty operations.

Durabile & Efficient

Span Tech conveyors are engineered for durability, built with high-quality materials to withstand tough environments and reduce maintenance costs. Their robust design ensures long-lasting, reliable performance, maximizing uptime and productivity for any operation.

Partnership

OEMs, Distributors, Integrators and End Users, choose Span Tech for innovative and reliable conveyor solutions tailored to unique needs. Our systems offer seamless integration, durability, and reduced maintenance, maximizing ROI and efficiency.

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

SpanTech’s EZGuide rail system has greatly improved change over times on our bottle filling line. We fill a wide range of bottle sizes and styles. The EZGuide system makes it easier and quicker to adjust between larger and smaller containers. One great feature is the lack of protruding rods from the sides of the conveyors. We are looking at installing this rail system on more filling lines in the near future.

I feel like Span Tech offered us more diversity, custom conveyors, especially for the products that we run and how we run them.

The sales and service personnel at Span Tech are always very professional and helpful throughout the entire process, from design phase, quoting, order processing and delivery of equipment. Quality equipment, professional service and knowledgeable personnel are why Arr-Tech’s choice for conveyor systems will always be Span Tech.

Paradise Tomato Kitchen has used Span Tech conveyors for our sanitary food pouch conveying systems for many years. These sanitary conveyors have provided the best cost of ownership, or the lowest net present value, of any processing conveyors we have used in our food manufacturing plants. These conveyors are easy to widen, lengthen or design for curves and angles to convey our flexible pouches between unit operations.

The quality of this product speaks for itself. Where the difference lies is in the quality of the organization. The whole Span Tech organization – Sales, Engineering, Service – works to serve customers’ needs, not just sell conveyors.