Shipping and Packaging prices are at an all-time high.

Considering the continuous increase of pricing, many companies have started shifting their packaging and shipping methods from the standard box method to a simpler more affordable bagging method. With this transition however, many problems began to arise. One of the main problems, from a conveyance standpoint, was the ability to take the bagged product from the initial vertical fill station and place it onto a horizontal conveying surface while consolidating the process into one fluid motion and without decreasing productivity time.

To the drawing board.

Span Tech took to the drawing board and quickly established two main goals.

-

Take product from a vertical position to a horizontal position without external manipulation, while maintaining label up product orientation.

-

Accomplish this orientation change while achieving high speed industry required rates.

Partnerships make perfect.

Span Tech and a well-known manufacturer of bagging equipment began working on a solution to these issues. Where many other companies where having trouble solving both of the issue together, Span Tech prevailed immediately.

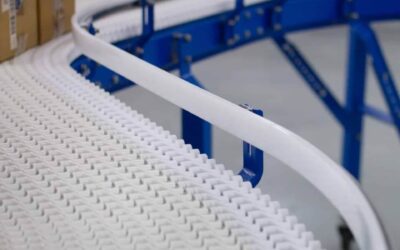

The solution was the 4-Wire Twist Conveyor.

Span Tech’s solution uses the standard Multispan Supertight chain series. The flexibility and modularity of this standard design allows the conveyor to start in a vertical position and twist about the center axis in 5 feet of conveyor length. From the moment the bag separates from the bagging unit it takes only 0.7 seconds for the product to clear the filling zone and make room for the next bag. This rate capability is well within the internal cycle times of bagging machines and can match any production rate that bagging machines can offer.

Span Tech conveyors offer a level of customization and modularity that provides near endless configuration possibilities. Once the twist is completed, Span Tech can offer solutions to fit any layout requirements. The conveyor can be configured to discharge product straight, left, right, or any angle of the main trunk line.

Find out more about the Twist Conveyor!