Having an inventory of spare parts is a vital part of keeping your conveyors running effectively and with minimal downtime. Keeping an inventory of necessary spare parts on hand or a quick list to reference when the time presents itself will help ensure the fastest and most cost effective solution to your conveyor problems.

Below we have listed some reasons why keeping up with your spare parts could be beneficial to your operation.

-

Efficiency

Having the proper parts on hand allows your company to get their operations back online faster, even after a major breakdown.

-

Expense

Spare parts may seem like are a large expense upon initial purchase, but their costs are minuscule compared to the costs of a breakdown without having spare parts on hand. Depending on the parts needed, the affected machines might need to be shut down while awaiting new parts. Vital parts may require an entire plant shutdown. Workers and production thus cease while the part is ordered, possibly fabricated, packaged, and shipped. This process could take days or even weeks to complete. Meanwhile, the costs mount for the plant that is sitting idle until the parts arrive. Missed production deadlines could cost the company money, time and valuable client relationships.

-

Proper Repair

Stories abound about company employees who, in an effort to avoid a major shutdown, perform a “patch job” on their equipment. The results are sometimes even more damaging to the machinery in a way that affects the conveyor operation. Making the parts available prevents the need for such shortcuts.

-

Shipping

Shipping costs for overnight/ next day air are sometimes as much as the costs of the required parts themselves; And paying these charges still does not guarantee the required item(s) are going to be delivered to the correct location, on time, and in perfect working order.

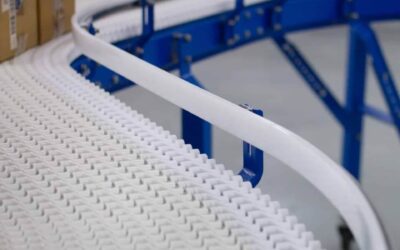

We at Span Tech never expect our systems to fail or cause you any problems, however we do understand that accidents happen and overtime normal wear and tear occur. This is why with every system sold we include a recommended spare parts list. This will ensure that you know what you need when you need it. Our goal is to keep your systems up and running for as long as possible and sometimes in order to do that; all it takes is a spare part.

When you order conveyors from Span Tech, we highly recommend adding spare parts to your order. If you already have our conveyors running in your facility, contact the Spare Parts Department. They will be happy to help you obtain a list of suggested parts for your conveyor.

Click here to learn more about our Support & Resources