1. Eliminate Downtime

As the saying goes, “Time is money.” The last thing your team needs is to pause their work due to machine failure. When you have spare parts on hand in your plant, any downtime caused by faulty equipment is practically eliminated. Why? Because you can instantly replace any pieces you need and get back to work. This creates an efficient, productive work environment for your employees and helps you ensure satisfaction for your customers.

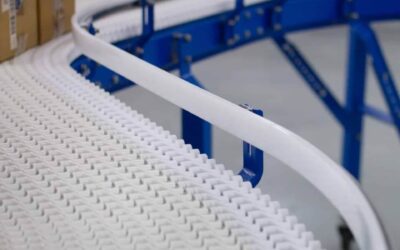

The biggest struggle in spare part management is creating an inventory. Span Tech’s spare parts department can help you compile a list of recommended spare parts to put together for your actual conveyors.

2. Increase Effectiveness

No business is immune from bumps in the road. When push comes to shove, your team can either be proactive or reactive. A strictly reactive manufacturing plant must take the time and effort to deal with any issue that arises. This can cause you to waste a lot of energy on problem solving rather than thinking about the bigger picture for your business. Most manufacturers are historically known for being reactive to events like equipment failure.

On the other hand, a proactive manufacturing plant has solutions to those problems before they even occur. One of the best ways to foresee and diminish obstacles your plant may have is by keeping replacement parts on hand.

In order to successfully create a functional spare part inventory, you need a more predictive approach to machine maintenance and failure. To do this, it’s important to note a collection of past purchase orders and overnight shipments. What parts were used? What’s your current inventory of those parts? Span Tech keeps this information on hand and can analyze the data, giving you the ability to see which items should be on hand at all times.

Get Spare Manufacturing Inventory from Span Tech

Since 1988, Span Tech has strived to exceed expectations and satisfy our customers. From specialty conveyors to spare manufacturing parts, we make it our mission to give you the very best. To order spare inventory for your facility, contact our Spare Parts team today!