CONVEYORS

SPECIALTY CONVEYOR SYSTEMS

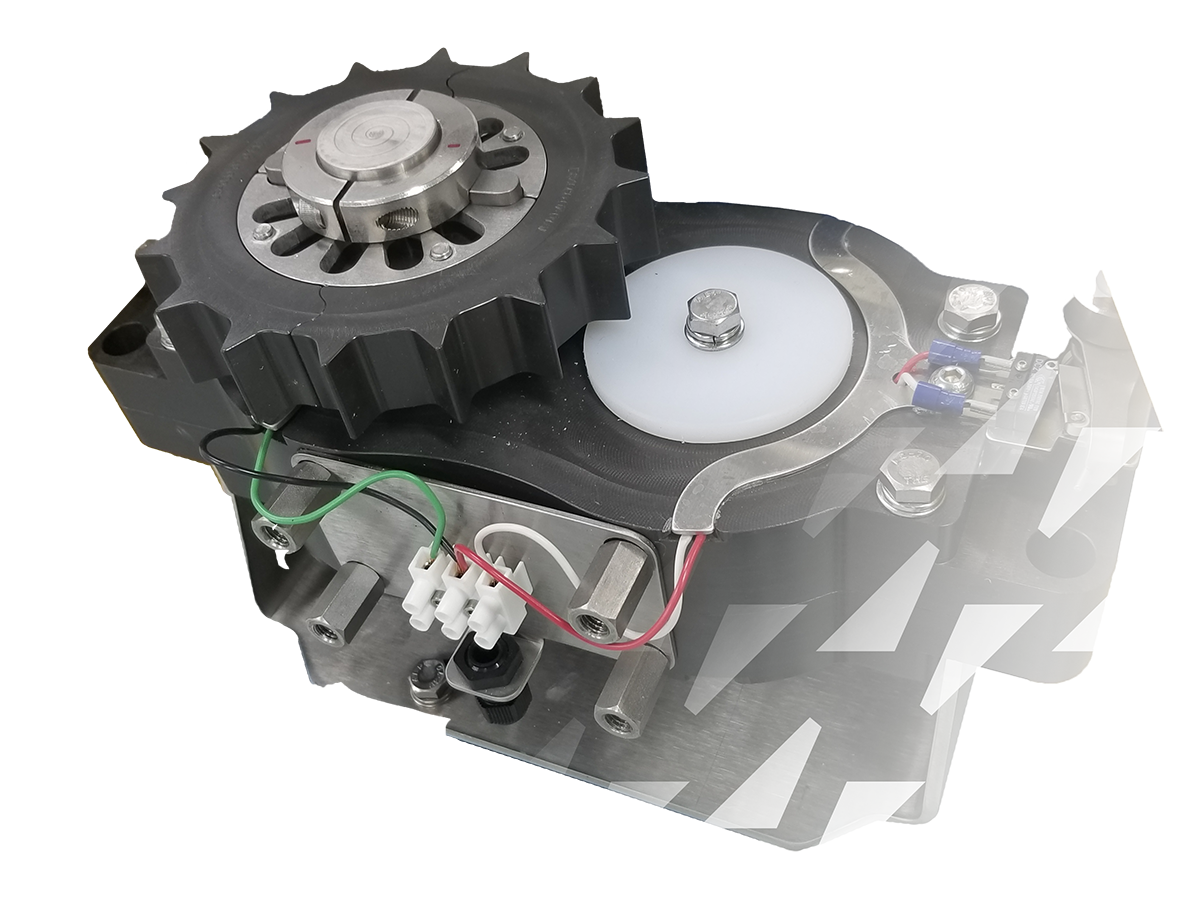

EZSpan Modular Belt Conveyor

Span Tech’s new line of “belt” conveyors. The EZSpan uses extremely-thin, modular conveyor chain to create a system that has many advantages over typical belt conveyor designs including: capability, maintenance, and price.

EZSpan Modular Belt Conveyor

Span Tech’s new line of “belt” conveyors. The EZSpan uses extremely-thin, modular conveyor chain to create a system that has many advantages over typical belt conveyor designs including: capability, maintenance, and price.

Tray Flipper Conveyor

A Pharmaceutical Distribution Center in Sumter, South Carolina needed to flip EPS trays upright for holding test tubes. Advanced Equipment Company and Span Tech created an over/under conveyor system with a simple guide to flip trays.

Tray Flipper Conveyor

A Pharmaceutical Distribution Center in Sumter, South Carolina needed to flip EPS trays upright for holding test tubes. Advanced Equipment Company and Span Tech created an over/under conveyor system with a simple guide to flip trays.

Spiral Cooler Conveyor

This Specialty Spiral Cooling Conveyor was designed for Advanced Equipment Company To solve an artisinal cracker companies cooling problems.

Spiral Cooler Conveyor

This Specialty Spiral Cooling Conveyor was designed for Advanced Equipment Company To solve an artisinal cracker companies cooling problems.

Lift Gate Conveyor

Easily access the interior of your closed loop conveyor with a Lift Gate solution.

Lift Gate Conveyor

Easily access the interior of your closed loop conveyor with a Lift Gate solution.

Twist Conveyor

Change product orientation without the use of external devices. Our twisted conveyors make product reorientation a breeze.

Twist Conveyor

Change product orientation without the use of external devices. Our twisted conveyors make product reorientation a breeze.

Choose Span Tech for SPECIALTY conveyor NEEDS

When standard conveyors just aren’t enough, we have something special to offer.

Need your conveyor to do something unordinary? Our specialty conveyors can do it all – from twisting to running underwater. We embrace your challenges to find the perfect, specialty solution.

Enhanced Efficiency

Enhanced Efficiency

With precise sorting, conveyors minimize bottlenecks, boosting overall productivity.

Improved Accuracy

Improved Accuracy

Advanced technology ensures accurate sorting, reducing errors and improving quality control.

Safety

Safety

Automated sorting reduces the risk of injuries associated with manual handling.

Reducing Manual Labor

Reducing Manual Labor

By automating the process of moving goods between different levels, these conveyors significantly reduce the need for manual labor, lowering the risk of injuries and increasing efficiency.

Scalability

Scalability

As business needs grow, sorting conveyors can be easily adapted and scaled to meet increased demands.

Industries

Why Choose Span Tech for your Specialty Conveyor Needs?

Customizable

SpanTech offers tailored solutions to meet specific operational needs, whether for delicate handling or heavy-duty operations.

Durabile & Efficient

Designed for continuous use in demanding environments, SpanTech’s conveyors maintain efficiency and reduce downtime, with low-friction operation leading to less wear and tear.

Partnership

SpanTech offers tailored solutions to meet specific operational needs, whether for delicate handling or heavy-duty operations.

By choosing SpanTech, businesses invest in a partnership that prioritizes innovation, quality, and customer satisfaction, offering a superior solution for their spiral conveyor needs.

Specialty Conveyor Articles

A Look Into the Accumulating Conveyor Applications Shaping Industries

Overview Accumulating conveyor applications are fundamental in today’s manufacturing environment, where efficiency and productivity are high priorities. These conveyors facilitate smooth product flow through different stages of production, helping to minimize downtime and reduce the need for manual intervention. As a result, accumulating conveyors are indispensable in maintaining high levels…

J. W. Allen Case Study

J. W. Allen Case StudyThe Perfect Partners: Rich\'s Products Corporation & Span Tech Span Tech\'s Customer Service Manager decided to visit Rich Food Corporation\'s Tennessee facility to inspect the wear on some of the Span Tech conveyors that had been in use there since 1994. He was surprised by what…

COBE BCT Case Study

COBE BCT Case StudySmall Parts Medical Manufacturer Optimizes Production Slow production rates and ergonomic problems were impacting the morale of COBE BCT\'s employees. The medical manufacturing company needed an innovative production line to streamline their process, but the highly technical nature of their work made finding a partner difficult. Enter…

Fleischer’s Bagels Case Study

Fleischer’s Bagels Case StudyFleischer\'s Growth Aided by Custom Designed Conveyor System As national demand for Fleischer\'s Bagels and their various products increased, so did the company\'s need for high volume, smoothly-automated production. Finding a universal yet intuitive solution seemed unlikely and expensive. Fortunately, it was Span Tech they called on…

Mr. Coffee Conveyor Case Study

Mr. Coffee Conveyor Case StudyThe workers at Mr. Coffee\'s Ohio-based plant were facing serious efficiency issues caused by the company\'s outdated plastic conveyors. Chains and sprockets needed frequent replacement. The whole cumbersome system had to be serviced regularly and the plastic couldn\'t cool quickly enough, and so on.Coffee filters produced…

Span Tech Nominated for Coolest Thing Made In Kentucky

Overview The “Coolest Thing Made in Kentucky” contest is an annual event that celebrates innovation, creativity, and manufacturing excellence within the state of Kentucky. Organized by The Kentucky Association of Manufacurers & Kentucky Farm Bureau Insurance, this contest invites manufacturers across various industries to showcase their most innovative and exciting…

OSHA Conveyor Safety Standards: A Roadmap for Ensuring Safe Practices

Overview In today\'s fast-paced industrial landscape, conveyor systems stand as the backbone of numerous manufacturing and distribution operations. These systems not only enhance productivity but also bring a set of safety challenges that cannot be overlooked. Recognizing this, the Occupational Safety and Health Administration (OSHA) has laid down stringent conveyor…

What Is an Accumulation Conveyor? A Comprehensive Guide to Accumulation Conveyor Systems

Overview Amid the bustling activity of today’s manufacturing and distribution sectors, the orchestration of product flow is a symphony of precision and efficiency, with accumulation conveyors conducting the tempo. These sophisticated accumulation conveyor systems not only move but also smartly manage the storage of products, accommodating fluctuations in the production…

5 Conveyor Transfer Methods: How to Transfer Products with Seamless Precision

OverviewIn today\'s fast-paced, highly automated industrial landscape, the significance of effective product transfer cannot be overstated. These transfers meld technological accuracy with operational effectiveness to facilitate smooth and reliable supply chains. Conveyor systems serve as the backbone of this critical operation. Engineered to accommodate a wide array of conveyor transfer…

What Is a Cleated Conveyor? The Benefits and Applications of Cleated Conveyor Belts

Overview Conveyor belts are an essential component of many manufacturing processes, and they come in various shapes and sizes to meet different needs. One type of conveyor that has gained popularity in recent years is the cleated conveyor. In this article, we will discuss what a cleated conveyor belt is,…

FAQ’s About specialty Conveyor Systems

How Do These Conveyors Improve Operational Efficiency?

Sorting and diverting conveyors streamline production lines. They improve operational efficiency by automating the sorting and merging processes, which reduces manual labor and speeds up the handling of products. This automation leads to faster processing times and increased throughput, which is crucial in high-volume industries.

Can Sorting and Merging Conveyors Be Customized for Specific Needs?

Yes, Span Tech’s sorting and merging conveyors are customizable. They are designed to be adaptable, allowing them to be tailored to specific operational requirements. This customization can include adjustments in conveyor size, shape, and the specific type of sorting or merging mechanism used, ensuring they fit perfectly into different production environments.

What Are the Maintenance Requirements for These Conveyors?

Maintenance requirements for our are minimal. The design and materials used in these conveyors ensure durability and longevity, reducing the need for frequent maintenance. However, regular inspections and routine maintenance are recommended to ensure optimal performance and to address any wear and tear over time.

How Do Sorting and Merging Conveyors Integrate with Existing Systems?

Span Tech conveyors are designed for easy integration with existing systems. They are built to be compatible with various types of packaging and processing equipment. This integration capability allows for seamless addition to existing production lines, enhancing their functionality without significant modifications to current systems.

What Do Customers Say About SpanTech?

To see what other satisfied customers have to say about their experience with SpanTech, visit our Testimonials page.

BRENT, SAMSUNG COMMUNICATIONS

“It made our life a whole lot simpler and easier.”

BRENT, SAMSUNG COMMUNICATIONS

“It made our life a whole lot simpler and easier.”

BRENT, SAMSUNG COMMUNICATIONS

“It made our life a whole lot simpler and easier.”