CONVEYOR SUPPORT

CONVEYOR SUPPORT STRUCTURES

Unmatched Stability and Flexibility for Your Conveyor System

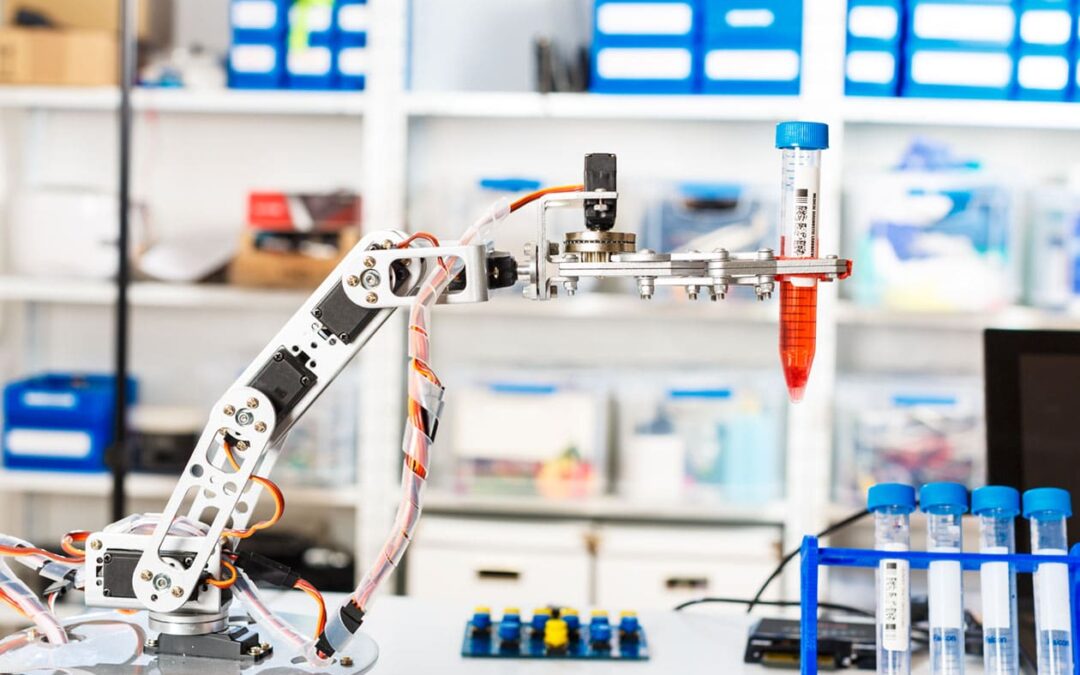

In any efficient conveyor system, reliable supports are essential for maintaining stability, ensuring safety, and optimizing performance. Span Tech Conveyor Supports are uniquely designed to provide robust, adjustable, and durable support for a wide range of conveyor applications. Our supports are engineered to ensure maximum stability, flexibility, and ease of integration, making them a valuable addition to any production environment.

Span Tech’s wide variety of standard and overhead conveyor support structures offer superior stability. We tailor our custom-made supports to keep your standard and overhead conveyor systems working in place with every use.

It’s no secret that Span Tech is the industry leader in standard and overhead conveyor design. While our high-tech conveyors are a big part of that, they’d be nothing without powerful structure. That’s where Span Tech’s durable supports come into play. They’re specifically designed to ensure your standard and overhead conveyor systems function in place and even allow for easy mobility when necessary.

Span Tech’s support structures are modular in construction and can be used on any one of our conveyors of the appropriate width. We offer the following types of structures for standard and overhead conveyor chain systems:

- Stainless steel

- Painted steel

- Anodized aluminum

Standard Supports

Span Tech standard stainless steel or painted mild steel supports are 2” x 2” tubing, with a 1” x 1” horizontal cross brace.

Drive Supports

Drive supports include an additional extended bottom brace to help stabilize the drive end of the conveyor.

Support Feet Options

Each support comes with the following optional feet types:

- Bolted to the floor.

- Free standing on padded feet.

- Lockable swivel casters.

Ceiling Support Options

Ceiling support brackets are used for all elevations over 84″ Top of Conveyor unless specified by the customer.

At Span Tech, we are committed to delivering innovative conveyor solutions that enhance productivity, safety, and operational efficiency. Our Conveyor Supports are designed to offer unmatched stability, flexibility, and durability, ensuring your conveyor system operates at its best. When you choose Span Tech, you’re investing in a system built to deliver consistent, high-performance results tailored to your specific needs.

Videos

Features & Benefits

Superior Stability for Smooth Operations: Span Tech Conveyor Supports are designed to provide a stable foundation for conveyor systems, minimizing vibrations and movement. This stability is crucial for maintaining smooth and consistent product flow, especially in high-speed or heavy-duty applications. With solid and secure supports, you can trust that your conveyor will run efficiently, reducing the risk of downtime and operational disruptions.

Durable Construction for Long-Term Reliability: Constructed from high-quality materials like stainless steel and heavy-duty aluminum, Span Tech Conveyor Supports are built to withstand the rigors of continuous use in demanding environments. Their robust construction ensures long-term reliability and reduces the need for frequent replacements, providing a cost-effective solution for conveyor stability.

Flexibility Across Applications: The adjustable and customizable design of our conveyor supports makes them suitable for a wide range of industries, including food and beverage, pharmaceuticals, packaging, and more. Their adaptability ensures they meet the unique demands of each application, providing reliable support where it’s needed most.

Modular Design for Easy Customization: The modular nature of our conveyor supports allows for easy customization and adaptation to different conveyor types and configurations. Whether you need supports for straight, curved, inclined, or declined conveyors, our products can be tailored to meet your specific needs.

Gallery

Why Choose Span Tech for Conveyor Supports

Customizable

Span Tech offers tailored solutions to meet specific operational needs, whether for delicate handling or heavy-duty operations.

Durabile & Efficient

Span Tech conveyors are engineered for durability, built with high-quality materials to withstand tough environments and reduce maintenance costs. Their robust design ensures long-lasting, reliable performance, maximizing uptime and productivity for any operation.

Partnership

OEMs, Distributors, and Integrators choose Span Tech for innovative and reliable conveyor solutions tailored to unique needs. Our systems offer seamless integration, durability, and reduced maintenance, maximizing ROI and efficiency. With comprehensive support from design to installation, Span Tech ensures success across industries, delivering value and a competitive edge.

By choosing Span Tech, businesses invest in a partnership that prioritizes innovation, quality, and customer satisfaction, offering a superior solution for their conveyor needs.

Conveyor Articles

A Look Into the Accumulating Conveyor Applications Shaping Industries

Overview Accumulating conveyor applications are fundamental in today’s manufacturing environment, where efficiency and productivity are high priorities. These conveyors facilitate smooth product flow through different…

J. W. Allen Case Study

J. W. Allen Case StudyThe Perfect Partners: Rich\'s Products Corporation & Span Tech Span Tech\'s Customer Service Manager decided to visit Rich Food Corporation\'s Tennessee…

COBE BCT Case Study

COBE BCT Case StudySmall Parts Medical Manufacturer Optimizes Production Slow production rates and ergonomic problems were impacting the morale of COBE BCT\'s employees. The medical…

Fleischer’s Bagels Case Study

Fleischer’s Bagels Case StudyFleischer\'s Growth Aided by Custom Designed Conveyor System As national demand for Fleischer\'s Bagels and their various products increased, so did the…

Mr. Coffee Conveyor Case Study

Mr. Coffee Conveyor Case StudyThe workers at Mr. Coffee\'s Ohio-based plant were facing serious efficiency issues caused by the company\'s outdated plastic conveyors. Chains and…

Span Tech Nominated for Coolest Thing Made In Kentucky

Overview The “Coolest Thing Made in Kentucky” contest is an annual event that celebrates innovation, creativity, and manufacturing excellence within the state of Kentucky. Organized…

OSHA Conveyor Safety Standards: A Roadmap for Ensuring Safe Practices

Overview In today\'s fast-paced industrial landscape, conveyor systems stand as the backbone of numerous manufacturing and distribution operations. These systems not only enhance productivity but…

What Is an Accumulation Conveyor? A Comprehensive Guide to Accumulation Conveyor Systems

Overview Amid the bustling activity of today’s manufacturing and distribution sectors, the orchestration of product flow is a symphony of precision and efficiency, with accumulation…

5 Conveyor Transfer Methods: How to Transfer Products with Seamless Precision

OverviewIn today\'s fast-paced, highly automated industrial landscape, the significance of effective product transfer cannot be overstated. These transfers meld technological accuracy with operational effectiveness to…

What Is a Cleated Conveyor? The Benefits and Applications of Cleated Conveyor Belts

Overview Conveyor belts are an essential component of many manufacturing processes, and they come in various shapes and sizes to meet different needs. One type…

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

SpanTech’s EZGuide rail system has greatly improved change over times on our bottle filling line. We fill a wide range of bottle sizes and styles. The EZGuide system makes it easier and quicker to adjust between larger and smaller containers. One great feature is the lack of protruding rods from the sides of the conveyors. We are looking at installing this rail system on more filling lines in the near future.

I feel like Span Tech offered us more diversity, custom conveyors, especially for the products that we run and how we run them.

The sales and service personnel at Span Tech are always very professional and helpful throughout the entire process, from design phase, quoting, order processing and delivery of equipment. Quality equipment, professional service and knowledgeable personnel are why Arr-Tech’s choice for conveyor systems will always be Span Tech.

Paradise Tomato Kitchen has used Span Tech conveyors for our sanitary food pouch conveying systems for many years. These sanitary conveyors have provided the best cost of ownership, or the lowest net present value, of any processing conveyors we have used in our food manufacturing plants. These conveyors are easy to widen, lengthen or design for curves and angles to convey our flexible pouches between unit operations.

The quality of this product speaks for itself. Where the difference lies is in the quality of the organization. The whole Span Tech organization – Sales, Engineering, Service – works to serve customers’ needs, not just sell conveyors.