Engineering the Perfect Solution

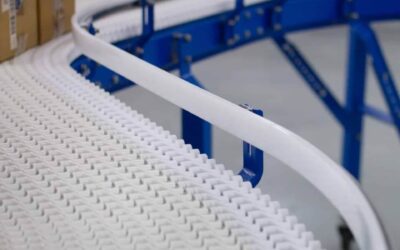

The role of an engineer in the Conveyor industry is extremely important in order to achieve the perfect solution for our Partners. Our Design Engineers are the backbone of our success, with over 300 years combined experience, drawing from a multitude of educational backgrounds and disciplines. They are experts in problem solving with flexible, out of the box thinking, able to design and fulfill complex needs.

Product conveyance is a necessity in virtually every manufacturing facility. No matter what the industry, raw materials are brought into the plant, products in process are transported from one operation to the next, and scrap is taken away. Processing and packaging require even more conveyance and all this requires our Design Engineers to first examine the application to understand the customer’s requirements, applications and conveyance objectives.

- Is the processor trying to gently convey delicate product, or is there a heavy, robust item to move from one operation to another?

- Does the application require high or low friction chain to successfully transport?

- Are there any special abrasive or load characteristics in the application?

- Conveyor chain speeds, application temperature, required chain life, impact resistance and other special considerations also play a critical role in Engineering the best systems possible.

Working closely with our partners, with hands-on working knowledge of our product development, implementation and maintenance of projects from initiation through completion, our Engineers design, engineer, manufacture, install, and support the conveyance and sortation applications – the end result, Engineering successful solutions!

Engineering the Future

At Span Tech we believe that one of the keys to our continued success is investing in the development of our Engineering talent. We partner with and utilize educational programs and relationships early on with budding talent. We contribute to the education of youth as early as Elementary throughout High School, and University as well as Technical School programs that can lead into Span Tech Internships and long term career employment. This ‘pay it forward’ thinking not only supports and contributes to the future of Engineering – it keeps Span Tech current and continually growing to better meet the needs of our Partners.

Here’s a few of the local programs we are part of:

Western Kentucky Industrial Partnership

Barren County High School | Stem Program (Science, Technology, Engineering and Mathematics)

Barren County High School | Engineering Advisory Board | CTE (Career Technology Education Facility)