A Closer Look at The Span Tech Conveyor Design

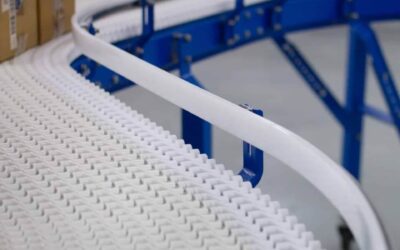

Before we dive into talking about conveyors, it’s important to distinguish the difference between our modular plastic conveyor chain and the commonly used phrase “conveyor belt.” Often confused as one in the same, the two are quite different. Just as the name suggests, a conveyor “belt” is just that — a belt. It’s a continuous, flat loop of fabric or plastic that transports products in a straight line (with very few exceptions.) Our modular plastic conveyor chain is different than a belt in that it is built from individual interconnecting rows of chain. This type of design can be made to a wide variety of widths and lengths depending on the needs of the application. Additionally, because these rows can collapse with each other, our modular chain has the ability to make curved, twisting, inclining and declining conveyors.

Modular Conveyor Parts and Functions

To get a better understanding of how our modular plastic conveyor chains work, it’s important to know how their parts function together. Span Tech’s unique conveyor design is made up of the following pieces:

Chain

The chain on our modular conveyor is what carries the product from one end to another. Our plastic chain conveyor types are customized for each order and can be made in thousands of variations. They can travel through curves, twists, inclines, declines and more, and they are extremely strong yet flexible.

Drive Unit

The drive unit is what pulls the plastic chain to help keep it in motion. It contains the conveyor’s drive sprockets, drive shaft and gearmotor. Drive units can be located at either end of our modular conveyor or even in the middle.

Idler Unit

Similar to the drive unit in appearance, the idler unit is found at both ends of the modular plastic conveyor chain. Unlike the drive unit, it doesn’t provide power. Instead, it allows the chain to move from the top to the bottom of the conveyor.

Bed Section

Located between the drive and idler units, the bed section is made of a side frame and wear strips. These strips capture the modular plastic conveyor chain and provide a low-friction running surface for it. Bed sections can be straight, curved, angled up or down, twisted or custom-made for just about any special application.

How Does a Modular Conveyor Chain Work?

It’s time we let you in on a little secret: Not all conveyors are created equal. Compared to all the different types of conveyors out there, Span Tech’s modular conveyors offer many unique features that help them stand out. Along with a distinct conveyor design, our products prove to be a cut above the rest with the following qualities:

No Chain Take Up

Thanks to our conveyor design, there is no need for a “catenary,” or chain take up section, to maintain chain tension in the system. All conveyors expand over time, and the total chain length may need to be shortened as a result. While this can be a bit of a hassle with other types of conveyors on the market, Span Tech conveyors are fairly simple to accommodate. Simply remove one or two rows of chain from the system, and you’re good to go. It’s that easy!

Individual Links

Unlike many other types of conveyors, Span Tech’s use individual links to make up the chain. This makes maintenance fairly easy and stress free if you ever have an issue. Rather than replace the entire modular plastic conveyor chain, you can simply repair the necessary parts. You’ll ultimately save money and be spared the headache that comes with investing in a brand new conveyor.

No Tracking Issues

Traditional belts require a system to keep the belt aligned and prevent it from “walking” off of the pulley. In comparison, Span Tech modular plastic conveyor chains don’t need this set up. Why? Our chains are kept in place within the bed section along the entire path of travel. The chain’s sprockets also keep the chain from traveling off of the drive unit.

No Black Residue Buildup

Quite often, a black residue can form after stainless steel rubs against certain plastics. This can leave items passing through the belt looking dirty and unsightly. You’ll never have to worry about this with our modular plastic conveyor chains. Span Tech’s stainless steel rods use a proprietary coating which prevents rubbing and eliminates black residue buildup.

Get A Top-Quality, Customized Conveyor Design from Span Tech

Since 1988, we’ve made it our mission to provide premium-quality modular conveyors for manufacturers and distributors. At Span Tech, we’re proud to offer the tightest turning radius for modular chain conveyors in the industry. Beyond that, we’re committed to providing our customers with unparalleled service and 24/7 support. Reach out to our staff to learn more about our standard straight, standard curving and speciality conveyors!