Defining the Material Staging Process Flow

Before we explain how Span Tech incorporates a material staging process flow, it’s important to understand what the concept is and how it works. What is staging in manufacturing? Simply put, material staging is transferring the items needed from different work centers to the assembly location. Materials are staged for production at a certain time, in a particular quantity, and at a designated staging area.

In warehouse manufacturing (WM), the flow of this process must be strategically planned and assessed for the best possible business structure. This form of production planning (PP) is a crucial part of your brand’s success and, when executed correctly, the process can help employees work more efficiently in the long run.

How Do You Do Material Staging in SAP?

Systems, applications and products (SAP) create a centralized system for manufacturers that enables the team to access and share data to create a better work environment for each employee on staff. Material staging in SAP requires gathering production items to be ready at a certain time and in a particular quantity. Using an SAP PP WM material staging system helps ensure all the required materials are in the designated production spot.

Once a production order is created, the SAP determines the necessary actions for material staging. In doing this, it examines the control cycle and determines the production storage bins in which the materials should be staged. Once this is complete, automatic material staging is activated in the SAP, and goods are transported to the correct production locations.

Integrating material staging in SAP WM helps production plants operate in an organized, effective manner that keeps business right on track.

Adopting a Material Staging Process Flow at Span Tech

Now that we’ve gone over all the essentials, we can get back to Span Tech’s experience with material staging in SAP. Before implementing this process, we realized our team often spent a great deal of time away from production to do the following:

- Searching for parts

- Gathering parts

- Visiting and revisiting work centers to see if needed subassemblies are ready.

The solution was to come up with a way that allowed production to continue without losing valuable time looking for parts. As Shakespeare once said, “All the world’s a stage.” Span Tech has taken that and put it into action with our material staging in SAP WM.

How Span Tech’s Material Staging Process Flow Works

Our material staging process flow is carried out with attention to detail and the utmost organization. It takes place in the following steps:

- 1. When an order is released for final assembly, a Bill of Material (BOM) is created. This list contains all parts needed for that order.

- 2. Purchased parts on the BOM are placed in a blue tote, and the tote is placed on a cart.

- 3. The cart is then used to gather manufactured parts from Span Tech’s work centers.

- 4. The cart is used to transport the purchased and manufactured parts to the designated area of assembly.

- 5. Assembly takes the cart and begins work.

This process is proving to be quite successful and extremely beneficial. Our awesome assembly team has been able to complete many jobs ahead of schedule and keep overtime to a minimum. Our goal is to eventually move this staging process to all of Span Tech’s work centers.

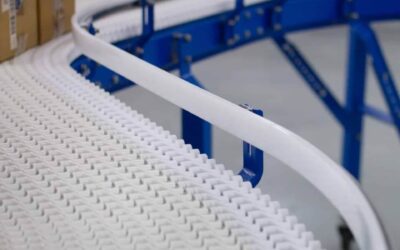

Get Custom Conveyor Solutions From the Experts at Span Tech

At Span Tech, we make it our mission to provide our customers with the utmost professionalism and highest quality they deserve during their experience with us. Our material staging process flow is just one of the countless ways we’re committed to delivering premium products and exceeding our clients’ expectations. Whether you’re interested in our standard conveyors, need troubleshooting assistance or are curious about our case studies, we’re here to go above and beyond. Contact us today to learn more about our services and what Span Tech can do for your manufacturing business!