CONVEYOR ADD ONS

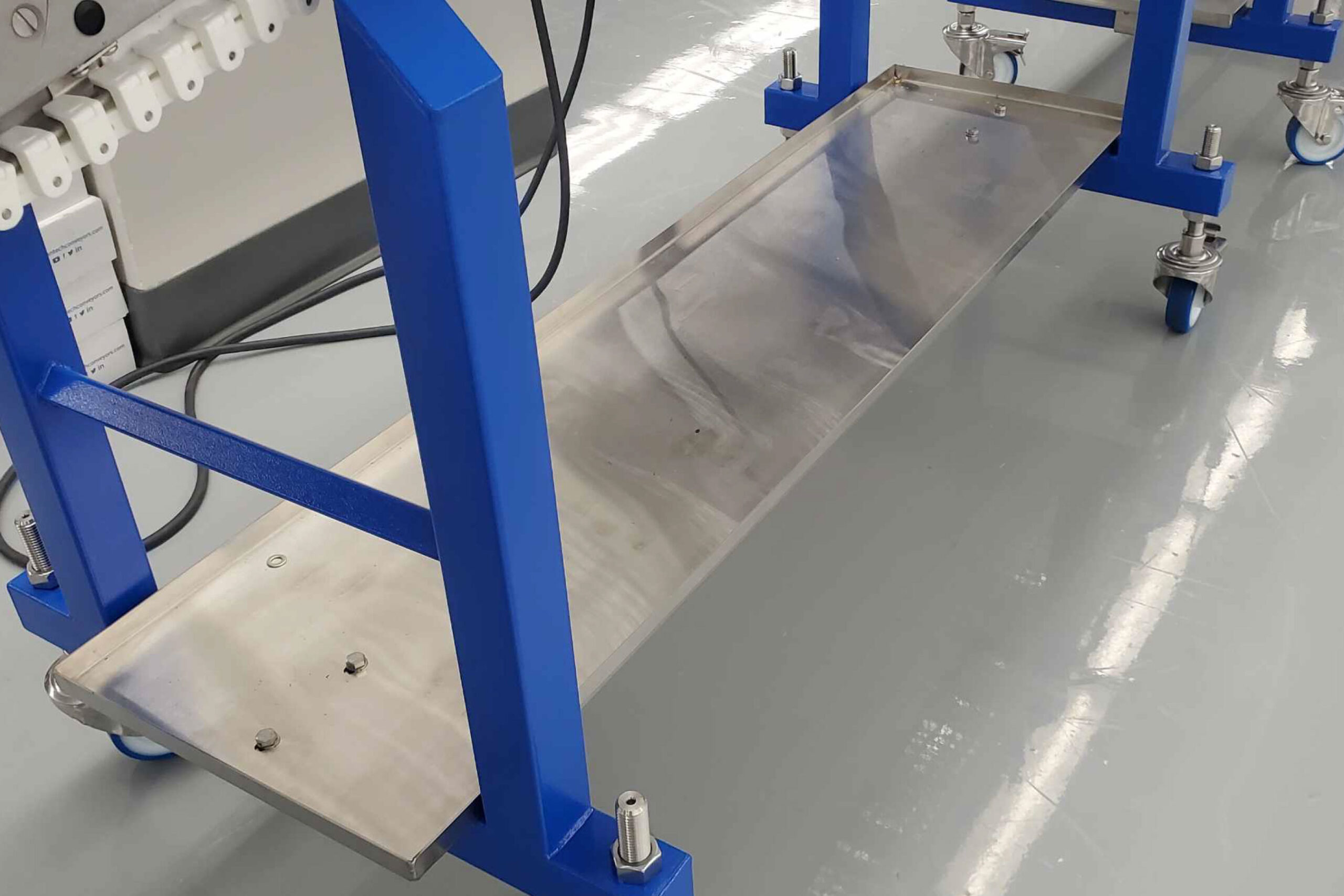

DRIP TRAY CONVEYOR ADD ON

Maintain Cleanliness, Safety and Efficiency with Superior Liquid Management

Maintaining a clean and safe production environment is crucial in industries where spills, drips, and leaks are common. The Span Tech Drip Tray Conveyor Add-On is designed to provide an effective solution for capturing and managing liquids, ensuring that your conveyor system remains clean, safe, and efficient. This add-on is ideal for industries such as food processing, pharmaceuticals, and packaging, where hygiene and safety are top priorities.

Drip Trays limit any potential damage that could occur from product dripping. Drip trays are designed to catch liquids and debris that could fall off of the conveyor and protect liquid/debris from falling onto walkways or other areas under the conveyor. Drip Trays can be equipped with drain plugs so liquid can be routed to a centralized drainage system.

Efficient Liquid Containment

The Drip Tray Add-On captures spills and drips, keeping the production floor clean and safe from slips and contamination.

Easy to Clean

Span Tech’s Drip Trays allow fast, efficient cleaning, minimizing downtime and maintaining high hygiene standards.

COMMONLY USED IN THESE INDUSTRIES

Reduce Mess & Maintain Cleanliness with Drip Tray Solutions

Span Tech’s Conveyor Drip Trays are designed to capture and manage liquids, debris, or other materials that may fall from products during transport. This simple yet effective add-on enhances cleanliness and safety in conveyor systems, making it an ideal feature for industries such as food processing, beverage manufacturing, pharmaceutical production, and industrial applications.

Applications For Drip Tray Conveyor Add Ons

Food Industry

- Capturing excess liquids, crumbs, or debris from products like raw meats, baked goods, or fresh produce.

- Preventing contamination by keeping spills contained and away from other products.

Beverage Industry

- Collecting spills or overflow from bottles, cans, or cartons during filling, capping, or washing processes.

- Maintaining a dry and safe work environment in high-speed production lines.

Pharmaceutical Industry

- Managing debris or liquid residues from medications, blister packs, or medical devices during production.

- Ensuring cleanroom standards are maintained by preventing contamination.

Industrial Applications

- Capturing metal shavings, lubricants, or other materials from industrial parts during transport.

- Enhancing workplace safety by preventing slippery conditions or equipment contamination.

Features & Benefits

Efficient Liquid Containment

The Drip Tray Add-On captures spills and drips, keeping the production floor clean and safe from slips and contamination.

Easy Cleaning

Span Tech’s Drip Trays allow fast, efficient cleaning, minimizing downtime and maintaining high hygiene standards.

Enhanced Hygiene

By managing spills, the Drip Tray ensures a clean environment, crucial for compliance in food, beverage, and pharmaceutical industries.

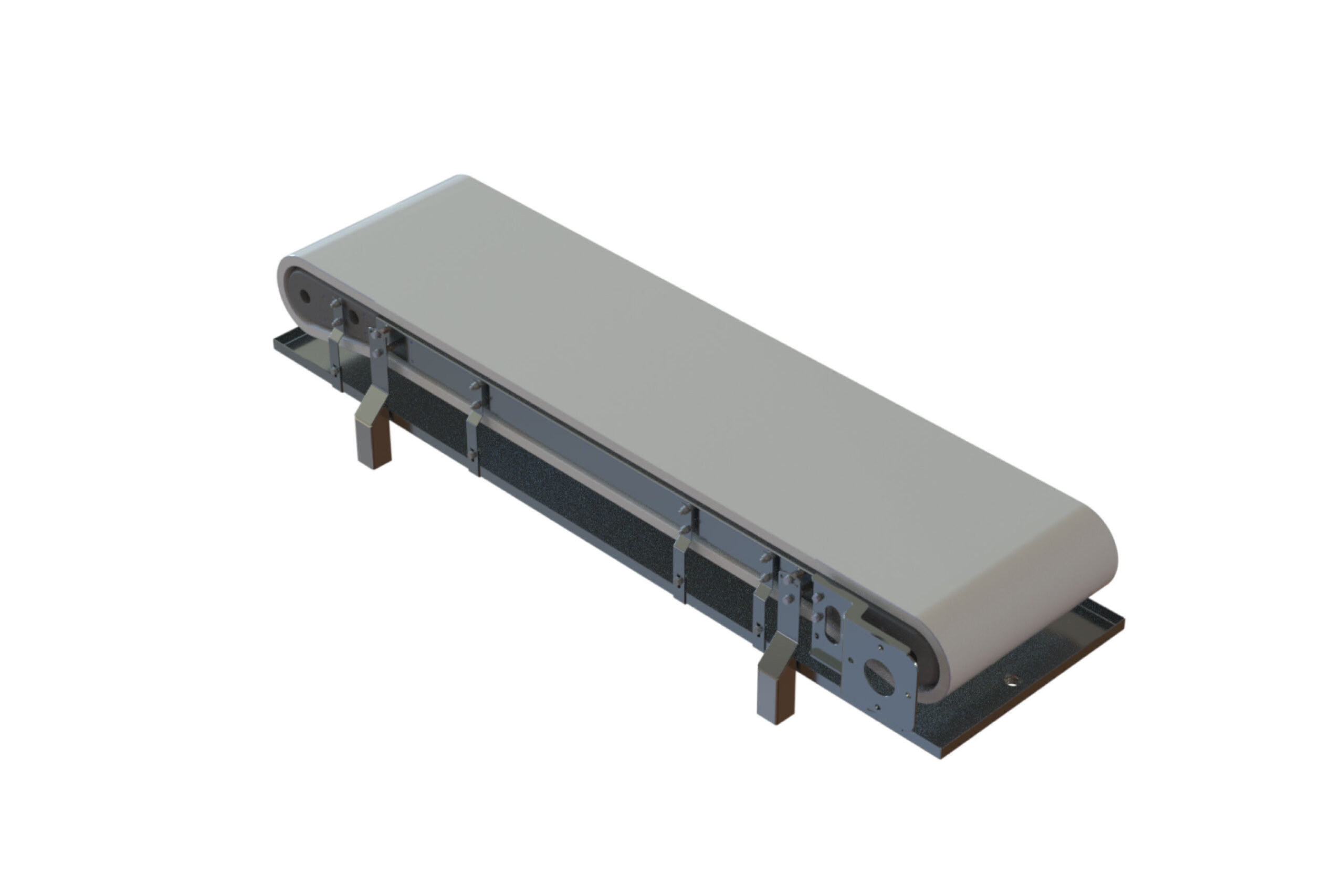

customizable

Span Tech offers tailored solutions to meet specific operational needs, whether for delicate handling or heavy-duty operations.

Durabile & Efficient

Span Tech conveyors are engineered for durability, built with high-quality materials to withstand tough environments and reduce maintenance costs. Their robust design ensures long-lasting, reliable performance, maximizing uptime and productivity for any operation.

Partnership

OEMs, Distributors, Integrators and End Users, choose Span Tech for innovative and reliable conveyor solutions tailored to unique needs. Our systems offer seamless integration, durability, and reduced maintenance, maximizing ROI and efficiency.

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

SpanTech’s EZGuide rail system has greatly improved change over times on our bottle filling line. We fill a wide range of bottle sizes and styles. The EZGuide system makes it easier and quicker to adjust between larger and smaller containers. One great feature is the lack of protruding rods from the sides of the conveyors. We are looking at installing this rail system on more filling lines in the near future.

I feel like Span Tech offered us more diversity, custom conveyors, especially for the products that we run and how we run them.

The sales and service personnel at Span Tech are always very professional and helpful throughout the entire process, from design phase, quoting, order processing and delivery of equipment. Quality equipment, professional service and knowledgeable personnel are why Arr-Tech’s choice for conveyor systems will always be Span Tech.

Paradise Tomato Kitchen has used Span Tech conveyors for our sanitary food pouch conveying systems for many years. These sanitary conveyors have provided the best cost of ownership, or the lowest net present value, of any processing conveyors we have used in our food manufacturing plants. These conveyors are easy to widen, lengthen or design for curves and angles to convey our flexible pouches between unit operations.

The quality of this product speaks for itself. Where the difference lies is in the quality of the organization. The whole Span Tech organization – Sales, Engineering, Service – works to serve customers’ needs, not just sell conveyors.